Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

Basic Information

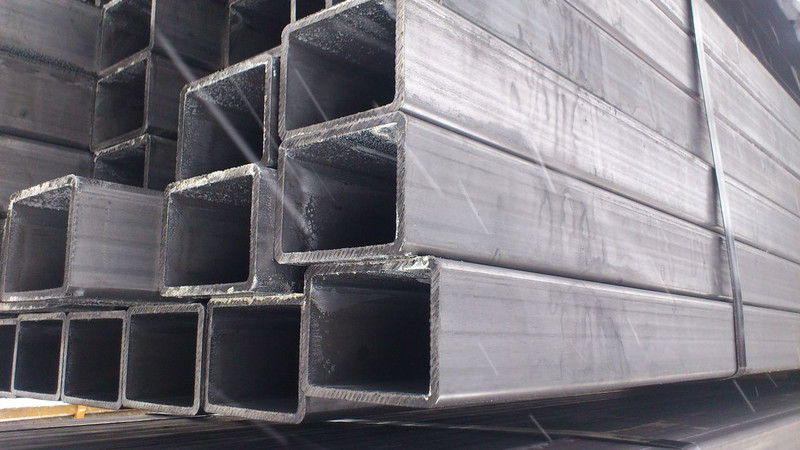

Pipe profile construction is performed according to the standard EN 10210 (hot-rolled) and EN 10219 (cold-rolled) of the following steel grades:

non-alloy structural steel S235JRH, S275JOH, S275J2H, S355JOH, S355J2H;

structural fine-grained steel – S275NH, S275NLH, S355NH, S355NLH, S460NH, S460NH.

The dimensions of square pipes range from 20x20 mm up to 400x400 mm with wall thickness from 2.0 mm to 20 mm. Rectangular pipes are produced in sizes from mm to 40х20 500х300 mm with wall thickness from 2.0 mm to 20 mm.

The pipe sections are manufactured according to standard EN 10305, DIN 2395 (steel grade S235JRH, E220), has the following dimensions:

square from 15x15 mm to 100x100 mm with wall thickness from 1.5 mm to 5.0 mm;

rectangular from 20x10 mm up to 120x80 mm with wall thickness from 1.5 mm to 5.0 mm.

Metal profile pipes of rectangular and square commonly used for the manufacture of parts having the form of flat frames and where necessary increased torque with a flat curve, which is very often required in load-bearing structures. Such use of metal specialized square tube is justified, as she has a moment of resistance to bending of flat 30% higher than equal-weight round tube. The use of solid shaped tube as a skeleton, in the manufacture of the shutters on the window or gate for the garage, increases the strength and resistance to mechanical deformations. Metal profile tubes collect a variety of ceiling, trusses, light steel structures, stairs, railings, pavilions, the trading equipment. If a flat curve is applied only to one side of the metal profile square tube, it is possible instead to use square tube of rectangular cross section. This will allow to achieve up to 10% reduction in total structural weight while maintaining the same strength characteristics.

Metal profile pipes find application almost everywhere – in the reinforcement of plastic Windows, construction of supporting structures, and even as a decorative or finishing items.

-

Payment Methods

We accept: