Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

Basic Information

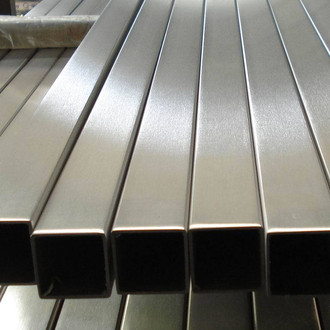

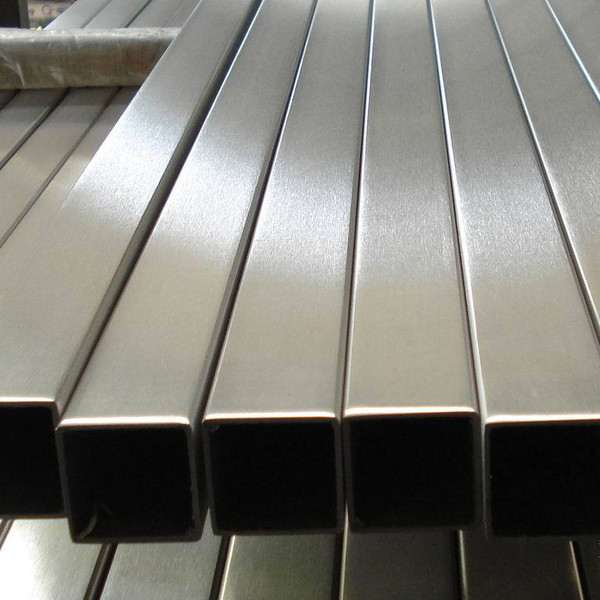

In the production of the profile stainless pipes, as a rule, use the following steel grades: AISI 201, AISI 202, AISI 301, AISI 303, AISI 304, AISI 304L, AISI 309, AISI 310, AISI 310S, AISI 314, AISI 316, AISI 316L, AISI 316Ti, AISI 321, AISI 329, AISI 403, AISI 410, AISI 410S, AISI 420, AISI 420F, AISI 430, AISI 430Ti, AISI 439, AISI 441 in accordance with DIN 2395.

Regardless of which stainless steel was used for the production of profile pipes have the following operational features:

high resistance to corrosion;

durability;

efficiency in the use of metal – about 25% compared with round stainless steel pipes;

easy installation;

the lightness of the structure;

increased strength due to stiffeners in a rectangular section profile.

In addition, the profile stainless pipes it is possible to produce structures of high complexity, which practically removes any restrictions on the use of these products.

The main application field of the profile stainless pipes is manufacture of metal structures and support elements for the equipment. Also products of this type are widely used to solve other problems in such areas as:

engineering;

pharmaceuticals;

chemical industry;

in the construction and decoration;

in the production of outdoor advertising;

in the manufacture of furniture;

Profile products are widely used not only as a structural element in the installation of equipment and construction of various structures, but in the domestic sphere. For example, a thin-walled pipe is an excellent material for the construction of suburban fences, greenhouses, sheds green.

-

Payment Methods

We accept: