Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

Suspended sludge filtration for wastewater treatme

James Mo

Contact person

Basic Information

| Place of Origin | Beijing China (Mainland) |

|---|---|

| Brand Name | OTC |

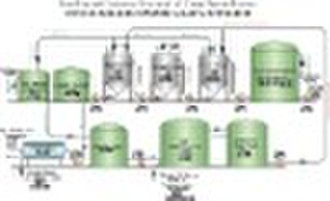

Recycling and Innocuous Treatment of Sludge with the SSF Wastewater Purification System With the SSF wastewater purification device, sludge is treated by chemical heated washing. This approach demands less investment and energy, and is safe, reliable, and environmental friendly. It is an efficient way of innocuous treatment and recycling of sludge. This treatment system includes sludge pretreatment, transportation, dosing, three hot washings and other building elements. Flow diagram for the process is as below. Most of the oilfield produced wastewater is treated with the “old three-step method”, of oil separation and removal -coagulation or sedimentation (or flotation) – filtration, which is time-consuming and complex for operation.It not only demands a large quantity of devices and equipments, but also may leave many problems after treatment. For example, grease trap can only remove the large-sized oil droplets, not emulsified oil or dissolved oil in water. Flotation, too, needs the demulsifier to work and makes it difficult to recover the oil. As oily wastewater contains high amount of salt and is corrosive, flotation devices which are composed of many rotating parts may suffer constant damages and prove to be unstable in operation. In addition, coagulation rarely has good treatment effect on oil and suspended solids in wastewater. Seeing these problems in oilfield wastewater treatment, our company independently developed the technology of SSF suspended sludge filtration wastewater purification, transforming the coagulative precipitation tank into an SSF wastewater purification device to replace the traditional process of flotation - coagulation - precipitation. The new technology has proved to be good and effective in operation: it not only greatly simplifies the process of wastewater treatment, but also reduces the treatment cost and workload for operation. As a new technology for removing suspended solids in wastewater, it is drastically different from the current method which is achieving separation with density difference. Based on Stokes’ Law and the theory of orthokinetic aggregation, this technology is advanced and has achieved stable separation. The technique can effectively remove oil of all types with advantages in short process and stable operation. After transformation, the injected water can easily reach C1 level indicators, to oil ≤ 5mg / L, SS ≤ 5mg / L. Transformation Advantages Removing the oil and suspended solids in wastewater stably for a long period of time as the follow-up filtration equipment will not be contaminated easily. Achieving effective spoil disposal, thus overcoming the problem under the old method that the water quality is seriously affected because of poor discharge of coagulative precipitation tank . After such transformations, it can do away with the follow-up filtration equipments, which greatly simplifies the wastewater treatment process, and reduces the investment and floor space. Large capacity and low operation costs. Simple operation and management.

Delivery terms and packaging

Packaging Detail: CONTAINER Delivery Detail: 30DAYS

Port: TIANJIN

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: