Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

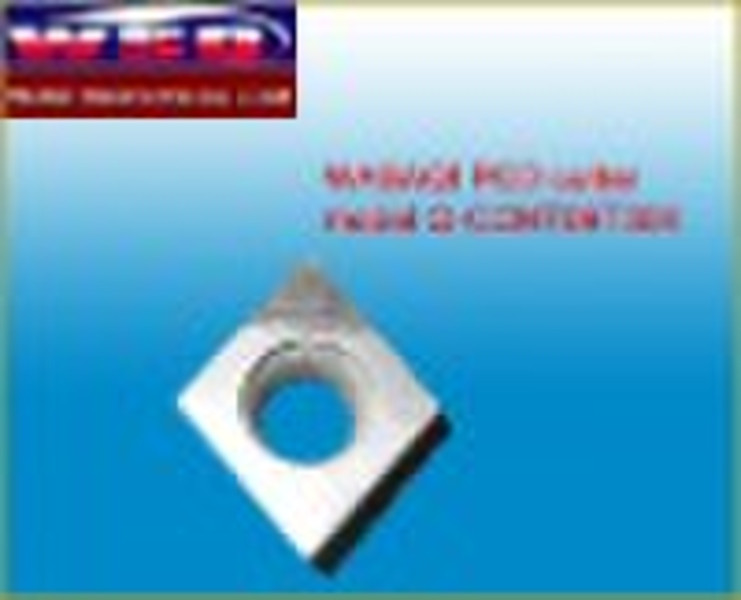

Square Diamond PCD inserts(Q-CCMT09T304)

original price: 8,00 USD

Foshan, China

Production capacity:

10000 Piece / Week

Foshan, China

86-757-22908587 22900798-604

Amy liu

Contact person

Basic Information

Square Diamond PCD inserts(Q-CCMT09T304) PCD Tool Description 1.Products imported American GE material 2. PCD tool improve process part surface fineness 3. Precision can reach 0.1 2 aluminium or copper in copper alloy nonferrous metal cutting processing Features 1.Long tool life,Excellent wear resistance,High fracture toughness.2.Suitable for the machining of aluminum alloys and non-ferrous metals,plastics,carbides etc.3.Control of micro chipping4.One-Use type inserts with chip-breaker offers good cutting surface by chip evacuation and cutting force.5.The cost is reducedother features 1.high productivity 2.high wearability 3.high thermal stability 4.unexampled law price 5.Polycrystalline Diamond /PCD is a diamond combo produced by synthetic diamond sintered with bond under high temperature and high pressure 6.it has very high wearability and high thermal stability. Its widely used in petroleum extraction, diamond machining, geology drill and mechanical processing tools. 7.PCD series have lower wearability than TSP series. 8.It is the first choice for nature diamond cutting & polishing nowadays. we also can offer other shape and size according to your requirement TypeDimension(mm)LCSdRCCMT0602026.46.352.382.80.2CCMT0602046.46.352.382.80.4CCMT09T3049.79.5252.384.40.2CCMT095304 9.7 9.525 2.38 4.4 0.4 SpecificationMaterialCCMW060204British DEBEERSCCMW060208British DEBEERSCCMW09T304British DEBEERSCCMW09T308British DEBEERSCCMW120404British DEBEERSCCMW120408British DEBEERSCNMG120404British DEBEERSCNMG120408British DEBEERSCCMH060204British DEBEERSCCMT09T302British DEBEERSCPMT120308British DEBEERSCPGT050202British DEBEERSCCGT060202British DEBEERSCCGT030102British DEBEERSCPGW080204British DEBEERSCPGW090304British DEBEERSCBGW120402British DEBEERSCBGT060204British DEBEERS PCD Tool Description 1.Diamond PCD cutting processing materials: points and non-ferrous metal nonmetal materials or tungsten carbide. 2.Including: aluminum, aluminum alloy and zinc alloy, aluminum, copper and copper alloy, tungsten, precious metal, metal matrix composites, compound wood, metal, acrylic, plastic, graphite and graphite composite material, glass fiber, FRP density fiberboard, laminated floor, ceramic, and other high wear-resisting material, etc. Advantage Advantage: the processing of nonferrous metal, make its surface Ra0.1 reach above, mirror-like effect, Higher material cutting, improve the production cycle, each more parts processing, Compared with the traditional cutting tools, cutting speed and feed rate significantly faster, Workpiece quality greatly improved, size, surface accuracy control of excellence, reduce scrap rate, The tool life long, the mechanical operation time, without any increase in new equipment investment circumstances, improve production capacity

Delivery terms and packaging

Packaging Detail: The plastic box packingsize: 72 x 42 x 15(cm) Delivery Detail: Within7days upon receipt of the desopit

Port: Zhongshan Port

Payment term

Letter of credit

Telegraphic transfer

Western Union

-

Payment Methods

We accept: