Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

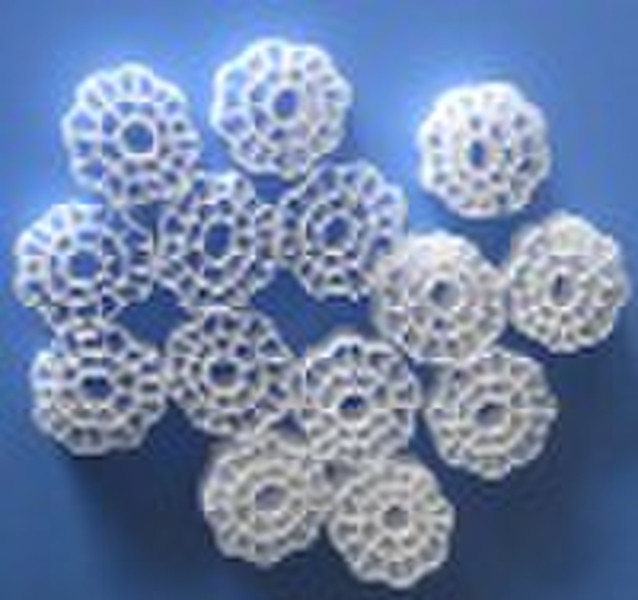

renewed suspended bio filler for water filter

qiufang li

Contact person

Basic Information

| Place of Origin | Jiangsu China (Mainland) |

|---|---|

| Brand Name | zeda |

suspended bio fillerApplied process and range:(1) thermofor biofilm reactor to remove organics and denitrify(2) active sludge processit combines biofilm and activated sludge process in the same treatment unit. it improve the ability to remove BOD/COD and strengthen the function of denitrification and dephosphorization. such process is suitable for the remounlding of activated sludge process, no need of rebuilding.(3)preposition denitration.(4)postposition denitration.Main technical parameters:Specification mm Ø25 * 9 Specific weight g/cm3 > 0.95 accumulation Pcs/m3 135256 Specific surface area m2/m3 >500 porosity % >95 Batching rate % 15 60 form-film time day 5-15 Nitration efficiency gNH4-N/m3·d 400 BOD5 oxygenation efficiency gBOD5/m3·d 6000 Suitable temperature °c 65 -35 Useful time Year over10 years main features: (1)geometricconfiguration based on hydrodynamics to strengthen the surface adhesive ability. it is polymer material, having high shock resistance. (2)large specific surface aera, many adhesive biologia.It not only provides the room for heterotrophic bacteria growing but also create the condition for autotrophic bacteria growing. Meanwhile, it is beneficial for the biologia to denitrification and dephosphorization. (3)no need of bracket, easy to fluidify, save energy consumption.The suitable specific weight makes the filler in suspended fluidization state, reducing the eneray consumption and increasing the shock and cutting of bubbles. In the same condition, the aeration amount can be lowered by above 10%. main advantages for the engineering application: (1) easy construction, quick form-film (for a week)and short-time start-up (2) long biological chain, biologia of variety and high catalytic activity (3) high-efficient decarbonization and strong ability to impact load. It can be above 6kg COD/m3 ·d (4) excellent denitrification and dephosphorization (5) less residual sludge produce (6) smaller land occupation.if it is active sludge process, the land occupation can be reduced 30% (7) simple and easy operation and management (8) less mainteinance and troubleshooting (10 lifespan) (9) according to the water quailty and specific process, add different amounts of filler into the aerobic tank, anaerobic tank and anoxic tank

Delivery terms and packaging

Port: SHANGHAI

Payment term

Letter of credit

Telegraphic transfer

Western Union

-

Payment Methods

We accept: