Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

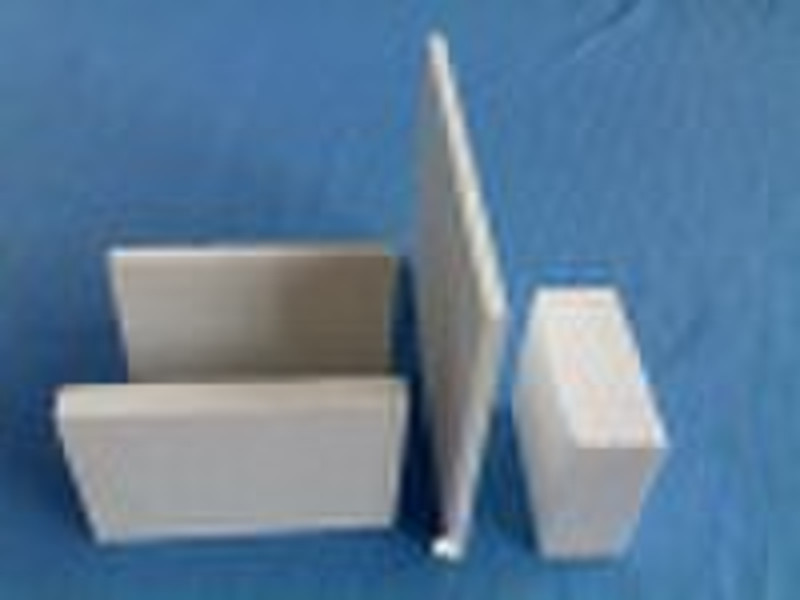

refractory fiber board thermal

Zibo, China

86-0533-7223858

MR XU

Contact person

Basic Information

| Brand Name | xiangmin |

|---|---|

| Place of Origin | Shandong China (Mainland) |

Mechanism of ceramic fiber board (Ceramic Fiber Board)Product Description: Processed by vacuum molding process, the strength of these products is higher than fiber blanket and vacuum molding carpet, suitable for products with high strength requirements of high-temperature areas. Technical characteristics: Low thermal conductivity, low heat capacity; excellent thermal stability and thermal shock resistance; high compressive strength, long service life; non-brittle material, toughness, good; size precision flatness good; easy to cut to install, easy construction; excellent anti-erosion properties; continuous production, fiber distributed evenly, stable performance; excellent acoustic noise performance. Application: Petrochemical industry: high-temperature furnace lining hot face material; Kiln Construction: hot-face refractory (alternative fiber blanket), has been heavy refractory lining, expansion joints; light: industrial and domestic boiler combustion chamber liner; iron and steel industry: expansion joints, back lining insulation, thermal insulation films and molded insulation; non-ferrous metals industry: tundish and flow slot cover for pouring copper and copper alloys; Ceramic Industry: lightweight kiln car structure and furnace hot face lining body, the furnace and the temperature zones separated by a fire block material; the glass industry: molten pool is lined insulation, burner blocks.Operating temperature: depending on material conditions of use, the heat source type and atmosphere.Project Name Normal Standard Purity type Alumina-type Zr-Al-type Zirconium type Classification temperature () 1050 1260 1260 1400 1400 1400 Operating Temperature () ≤ 1000 1000 1100 1200 1300 1400 Bulk Density (kg/m3) 280 ± 15 280 ± 15 280 ± 15 280 ± 15 280 ± 15 280 ± 15 Permanent linear shrinkage (%)(Volume density 285kg/m3) 1000 × 24h ≤ -4 1000 × 24h ≤ -3 1100 × 24h ≤ -3 1200 × 24h ≤ -3 1300 × 24h ≤ -3 1400 × 24h ≤ -3 Thermal Conductivity (W / mk)(Volume density 285kg/m3) 0.085 (400 ) 0.132 (800 ) 0.180 (1000 ) Compressive Strength (MPa)(Thickness direction of compression 10%) 0.5 0.5 0.5 0.5 0.5 0.5 Chemical Composition (%) AL2O3 44 - 45 45 - 46 47 - 49 52 - 55 47 - 51 39 - 40 AL2O3 + SiO2 96 97 99 99 ---- ----- AL2O3 + SiO2 + ZrO2 ---- ----- ---- ---- 99 99 ZrO2 ---- ---- ---- ---- 8 - 9 15 - 17 Fe2O3 "1.2 "1.0 0.2 0.2 0.2 0.2 Na2O + K2O ≤ 0.5 ≤ 0.5 0.2 0.2 0.2 0.2 Product Code XMGX-115 XMGX-215 XMGX-315 XMGX-515 XMGX-615 XMGX-715 Product Specification (mm) 900 * 600 * 50; 600 * 400 * 25 (the other specifications according to user requirements production)

Delivery terms and packaging

Packaging Detail: carton box Delivery Detail: within10-15days

Port: qingdao

-

Payment Methods

We accept: