Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

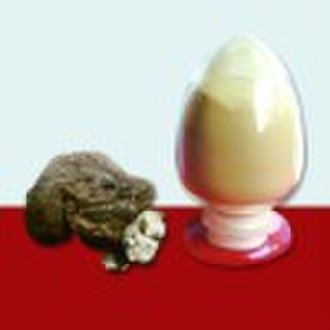

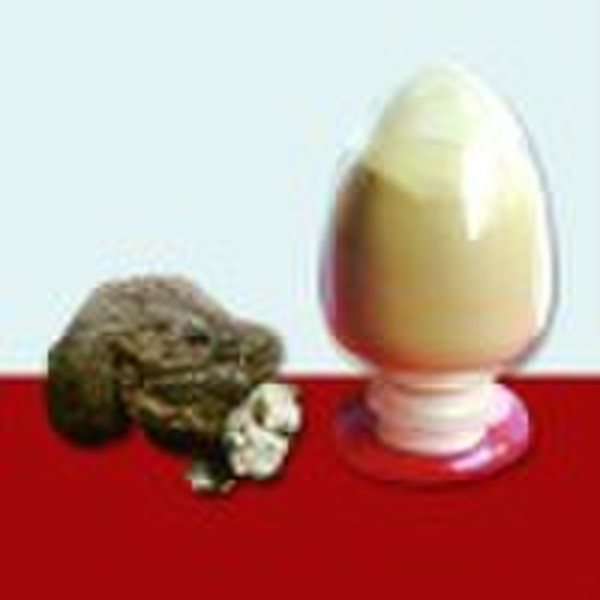

Poria cocos polysaccharide

original price: 300,00 USD

Shenzhen, China

Production capacity:

300 Kilogram / Month

Jiwen Zhang

Contact person

Basic Information

| Packaging | Drum |

|---|---|

| Place of Origin | China |

| Grade | 1 |

| Brand Name | kang dao |

| Type | Mushroom Extract |

| Form | Powder |

Poria cocos polysaccharide Poria cocos is a very old and widely used herb especially in Chinese medicine. Poria cocos is a solid fungus also known as Fu Ling, Poria, Tuckahoe, Indian bread, or Hoelen, and grows on the roots of old, dead pine trees. Poria cocos has been traditionally used as a tonic to benefit the internal organs. Poria is normally white in color, and also called "white poria". The variant with light red color is called "red poria".Main chemical constituents of Poria cocos includes: beta-pachyman, a polysaccharide beta-pachymarose, several organic acids such as tumulosic acid, eubricoic acid, pinicolic acid, and pachymic acid, 3-beta-hydroxylanosta-7,9(11). 24-trien-21-oic acid, chitin, protein, fat, glucose, sterols, lecithin, gum, choline, etc. Poria cocos has tranquilizing, diuretic, and cardiotonic effects. Poria cocos also lowers blood sugar levels, and has anti-bactrial, immunotonic, anti-cancer effects. Poriacocos mainly contain polysaccharide, carboxymethy pachyman and triterpene. It is anew type of immunoregulation nutritive health food. It adopts Tuckahoe, a pure natural Chinese medicine, and it fefined through mordern high techniques and advanced crafts. It can strengthen the physiological activities and prevent disease. It can promote the functional recovery of the human immunity ststem. It can induce or promote induction of the interferon and leukocytic opsonin. It has indirect antiviral and anti-neoplastic effection and lessens the side effects of radiation and chemotherapy. It can protect livers, lower the enzyme(CPT), prolong the life, calm the nerves, strengthen the stomach, improve looks and so on. Quality parameters Character Offwhite powdera little moisture absorption Polysaccharide Content 30% 60% Solubility(water) Soluble Heavy metal parameters As≤1.0ppm Cd≤2ppm Cr≤1ppm Pb≤2ppm Hg≤0.5ppm Sanitation indicators Bacteria≤1000/g E.Coli and Mite not detected Mould≤100/g Loss on Drying 9%

Delivery terms and packaging

Packaging Detail: Outer Package: Paper Box Inner Package: Foil,All the package could meet International Package Standard Delivery Detail: within 10 days after order confirmation

Port: Shenzhen

Payment term

Telegraphic transfer

MoneyGram

Western Union

-

Payment Methods

We accept: