Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

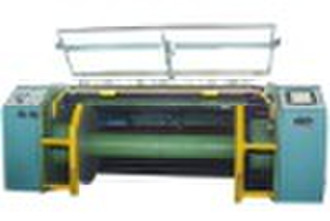

HFGA121 High Speed Direct Warping Machine

Jiangying, China

0086-510-86366219

Dan Yao

Contact person

Basic Information

| Place of Origin | Jiangsu China (Mainland) |

|---|---|

| Brand Name | H-FANG |

| Model Number | HFGA121 |

Technical characteristics ·DELTA inverter ensure wide speed scope and constant surface winding speed. ·SEIMENS PLC for fully automatic programmable control on loading/doffing, clamping, pressuring, start/stop of machine, speed adjusting and yarn broken memory. ·10.4-inch PRO-FACE touch screen from Japan for date setting/changing/display and trouble shooting and analyzing. ·Special disc spring shockproof device for high reliability and steady of machine running and starting/stopping. ·Perfect pneumatic system for controlling beam lifting, clamping and pressurizing of press roller, also provide pressure for the hydraulic braking system. ·Hydraulic disc brakes originally for SANTANA Car for beam and press roll, braking force adjustable automatically according to different rotating speed. Two high quality electromagnetic brakes for guide roller, side brake at low speed and double sides brake at high speed to ensure good brake effect. ·Side frames made of high quality cast iron, good in structure, high in rigidity and more reliable in running. ·The roll press beam parallelly along the fixed straight rail inclined 15o , no vibration and less noise when machine running at high speed, pressure adjustable steplessly, can be displayed on the pressure gauge, this ensure the optimal yarn build-up. The press roller swings away upon braking. ·Strong beam supporting mechanism and safety device ensure beam running at high speed not to drop in case of sudden power or gas failure, avoid injuring operator. ·Special interlocked counting length device for main shaft and press roll ensure high precision measurement. ·Expansion reed movable up and down, left and right, intermittent blowing device available to keep comb clean. Blowing time and interval can be set freely. The swing and frequency of expansion reed differs from different rotating speed of beam.

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: