Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

Basic Information

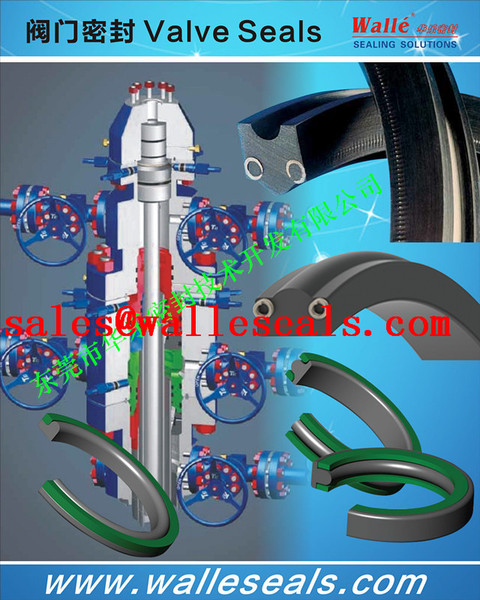

FS seals

FS seals is designed to provide high performance static sealing against rough casing and tubing. It reduces installation time, correct placement in the housing and simplify installation method.

The FS seals technology is especially suited for applications where wide tolerances and varying surface finishes create difficult sealing conditions. It is utilized as a large cross-section interference seal to bridge large extrusion gaps associated with sealing on rough mill casing. The shape of the FS seals design allows for a high level of deflection across the full range of operating temperatures, without the risk of gland overfill.

Features and Benefits

● Range of elastomeric and spring material combinations

● Pressure energized

● Can be retrofitted to existing groove

● Ability to seal large or inconsistent extrusion gaps

● Flexible seal for easy installation or field repair

● Handles aggressive chemicals and abrasive oilfield applications

● Large cross-section / diameter ID version of S- seal

● Standard and custom sizes

Applications and Services

● Casting and tubing hanger

● Stab-in operations

● High pressure pipelines

● Hydraulic Cylinders

● Fluid and gas applications

● Wide ranges of temperature and pressure

Manufacturing and Production Processes

● Molding

Sizing

● API standard Casing Sizes

● Custom Sizing Options

Material Selection

Base Material Useful Temperature Range Application

℉ ℃

NBR -25 to +250 -31 to +121 Petroleum oils and fuels, water, glycols, silicones

HNBR -45 to +300 -42 to +148 General service. Improved wear and abrasion resistance.Good for Harshwell service, water steam and amine corrosion inhibitors.

FKM / FPM -10 tO +430 -23 to 220 Suitable for high temperature, aliphatic and aromatic hydrocarbons.

FEPM / Aflas 0 to +450 -17 to +232 Sour petroleum oils and fuels, acids, bases, amines, steam

Custom compounds Please contact us, we will make per your request

Nominal Ø BB Bore DD Housing

Casing Size Depth

(* see Note) mm inch mm inch

103.19 4.063 21.21 0.835

119.06 4.688 21.21 0.835

133.35 5.25 21.21 0.835

146.05 5.75 21.21 0.835

152.4 6 21.21 0.835

158.75 6.25 21.21 0.835

171.45 6.75 21.21 0.835

177.8 7 21.21 0.835

184.15 7.25 21.21 0.835

200.03 7.875 21.21 0.835

209.55 8.25 21.21 0.835

225.43 8.875 21.21 0.835

228.6 9 21.21 0.835

250.83 9.875 21.21 0.835

260.35 10.25 21.21 0.835

276.23 10.875 21.21 0.835

282.58 11.125 21.21 0.835

304.8 12 25.4 1

333.38 13.125 25.4 1

336.56 13.25 25.4 1

374.65 14.75 25.4 1

381 15 25.4 1

390.53 15.375 25.4 1

441.33 17.375 25.4 1

508 20 25.4 1

560.39 22.063 39.69 1.563

662 26.063 39.69 1.563

814.4 32.063 39.69 1.563

Delivery terms and packaging

Port: Huangpu

Срок доставки: 15 days

Package Type: Carton

Weight Incl. packaging: 1 Kilogram

Packing size: 5x2x1 Centimeter

Срок доставки: 15 days

Package Type: Carton

Weight Incl. packaging: 1 Kilogram

Packing size: 5x2x1 Centimeter

Payment term

Telegraphic transfer

Cash

Paypal

Western Union

-

Payment Methods

We accept: