Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

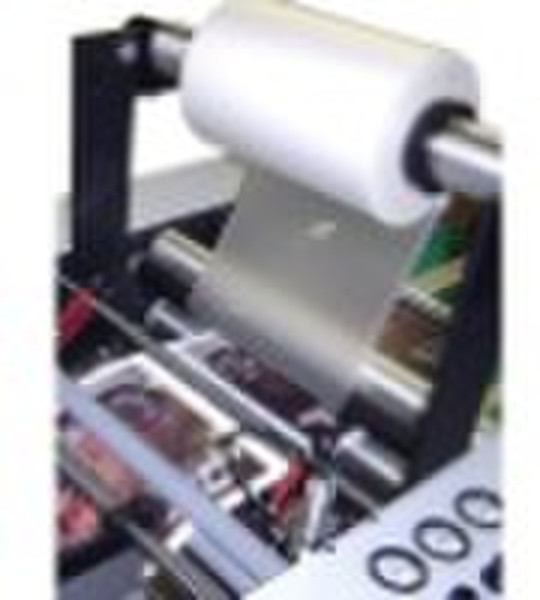

BOPP Thermal Lamination Film;Hot lamination film;T

original price: 3 000 USD

China

Production capacity:

360 Ton / Month

Xiujun Guo

Contact person

Basic Information

The basic layer of film doesn't melt at laminating temperature.It is produced through the extrusion coating process.where the adhesive is applied to the film.when heated,the adhesive melts to a tacky condition where is married to the printed sheet under extreme pressure.when cooled to a solid again.the adhesive provides a high strenght chemical bond.our adhesives give superior bond strengths on a wide variety of subject material.such as paper,board,metal ,plastics,etc Process Parameter: Equipment for laminating film:dry and wet film laminator Temperature:85-100 0C Special:100 -120 0C Roller pressure: 10-18 Mpa Speed: 8 - 50 m/min Remarks:Special laminations refer to those with thicker ink,solid color,high moisture content and bigger size paper. Bopp thermal lamination film Gloss & Matt) SPECIFICATION & PARAMETERSPECIFICATION24MIC GLOSS25MIC GLOSS27MIC GLOSS30MIC GLOSS25MIC MATT27MIC MATT30MIC MATT THICKNESS(UM)BASE12121518151518EVA12131212101212TOTAL242527 30252730 WEIGHT/kg45.0443.2240.136.1544.2440.8436.87kg/0.2220.02310.0250.027660.02260.024480.02712 Width140 190 200 360 390 440 540 590 780 880 1080 1320 1400 1600 1800 Upon customers requirement Lenghth300 - 6,000 more or less 10% allowed Corona Treatment SideONE SIDEBOTH SIDE Connector2 Less than 2 TENSILE STRENGTH MD:3.1*106 dyne/cm CD:6.1*106 DYNE/cm Paper Core(interDia25.4mm(1 inch);58mm(2.25 inch);76mm(3 inch)PS24MIC=2.4C=0.945MIL25MIC=2.5C=0.984MIL27MIC=2.7C=1.06MIL30MIC=3.0C=1.18MIL

Delivery terms and packaging

Packaging Detail: Two thousandmetres and Three thousand metres product------one roll in a carton,Export packing Delivery Detail: 30 Working days

Port: Shunde port

Payment term

Telegraphic transfer

-

Payment Methods

We accept: