Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

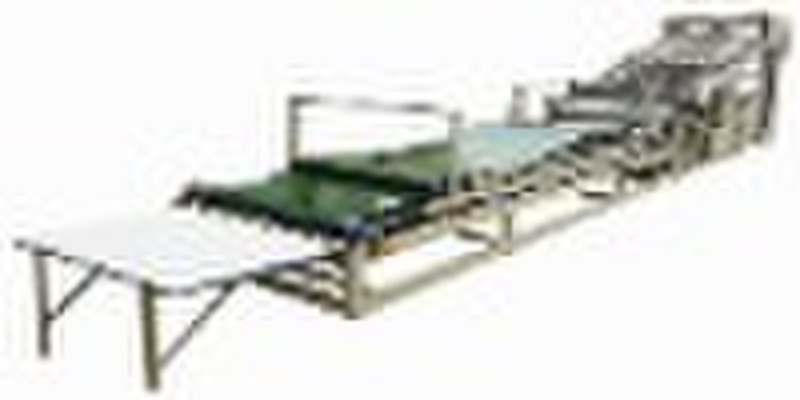

Automatic Flute Laminator

Chic Zhang

Contact person

Basic Information

Introduction Automatic flute laminator using surface paper and bottom paper feed system automatically, applies for color printing paper (cardboard) and corrugated paper mounting affixed to the high-speed automatic. The machine consists of Paper Feeder, Upper paper Transporting Part, and lower paper Transporting Part, Gluer, Glue Laminator and pressure-bed conveyor. The feeder push the upper paper and turn up to locator, meanwhile the corrugated paper have been speedily sent out with glue. Then upper paper is laminated with corrugated paper. Finally, both of two sheets are laminated again by upper and lower press roller and sent out. 1, Automation Control System a) Adopt imported low-voltage electrical equipment; touch screen and PLC control systems. It includes a Stepping control system, which is simple structure, stable and reliable control. b) Use inverter speed control, which is saving electricity. c) It can display operating status and fault status and shutdown automatically. d) When there is no glue, no paper or paper overlaps, the automatic alarm can sound and the machine shutdown automatically. 2, Ways to transmit Surface Paper. The nozzle-type Feeder head, which is similar to overlapping transmission of color printing machine, import paper with slow speed to ensure that the transmission stable and reliable. 3, Side Guide Adopt Side Edge Control used in Color printing machine to pull edge automatically, which is stable and accurate. 4, Front Guide Adopt paper baffle plate to block upper paper, low paper can operate with high speed in accordance with gap adjustment between rollers. Upper Paper can always exceed, which is accurate and reliable, maintenance-free and non-replaced. 5. Ways transmit Low Paper: a) Adopt strong-wind Suction Belt to feed paper. And adopt Independent Stepper Motor to drive Suction Valve. Ensure to have air to input whether its wind valve turn off or not, guarantee motor not to get high temperature and durable. b) Ways of Belt conveyor: use powerful Torque-and-stepper Motor to drive, which is high speed and accurate, stable and maintenance-free. 6, Roller conveyor When Host motor shuts down, it uses an independent motor to drive the upper roller and the quantitative-adjustment glue roller to rotate with low speed. So save electricity. While host motor operates, it drives upper roller and others rollers in synchronization, but the quantitative adjustment glue roller always maintain a low speed to ensure that the glue does not splash. 7, Gap adjustments: Adopt chain double roller to adjust in synchronization, which saves time. 8, Ways of paper conveyor Upper paper use overlapping type to feed paper. Low paper use double roller to operate in synchronization and take the paper operating way short and fast. Technical data: ModelVFLA1100VFLA1300VFLA1450VFLA1600Max. feeding size(mm)1100*11001300*11001450*11001600*1300Min. feeding size(mm)350*350500*370500*370500*370Paper Weight (g/m)250 - 450250 - 450250 - 450250 - 450Suitable PaperA,B,C,D,E corrugated paper ≤8 MMLaminate Accuracy2-5MM Adjustable(Precision ±1.5mm)Machine Speed100 pcs/minTotal Power(kw)14151518Dimension(m)13.9*2.22*2.6813.9*2.22*2.6814.1*2.41*2.6815.62*2.61*2.68Weight(Ton)6.86.87.59.0

Delivery terms and packaging

Packaging Detail: The machine bodies are wrapped by plastic film Delivery Detail: 30 days

Port: Shenzhen

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: