Katalog

-

Katalog

- Auto & Motorrad

- Bauwesen und Immobilien

- Bekleidung

- Büro- und Schulartikel

- Chemikalien

- Dienstleistungen für Unternehmen

- Eisenwaren

- Elektrische Geräte & Zubehöre

- Elektronische Bauteile

- Energie

- Galanteriewaren

- Geschenke und Kunsthandwerke

- Gesundheit und Medizin

- Gummi und Kunststoffe

- Haus und Garten

- Haushaltsgeräte

- Koffer, Taschen & Hüllen

- Landwirtschaft

- Lebensmittel und Getränke

- Licht und Beleuchtung

- Maschinen, Geräte und Werkzeuge

- Maschinenteile und Herstellung Dienstleistungen

- Messapparat und Analysegerät

- Mineralien und Metallurgie

- Möbel

- Schuhe und Accessoires

- Schönheit und Körperpflege

- Service Geräte und -Ausstattung

- Sicherheit und Schutz

- Spielzeuge und Hobbys

- Sport und Unterhaltung

- Telekommunikations

- Textil und Lederware

- Transport

- Uhren, Schmuck, Brillen

- Umweltschutz

- Unterhaltungselektronik

- Verpacken und Drucken

- Werkzeuge

- Überschüssiger Warenbestand, Lager

Filters

Search

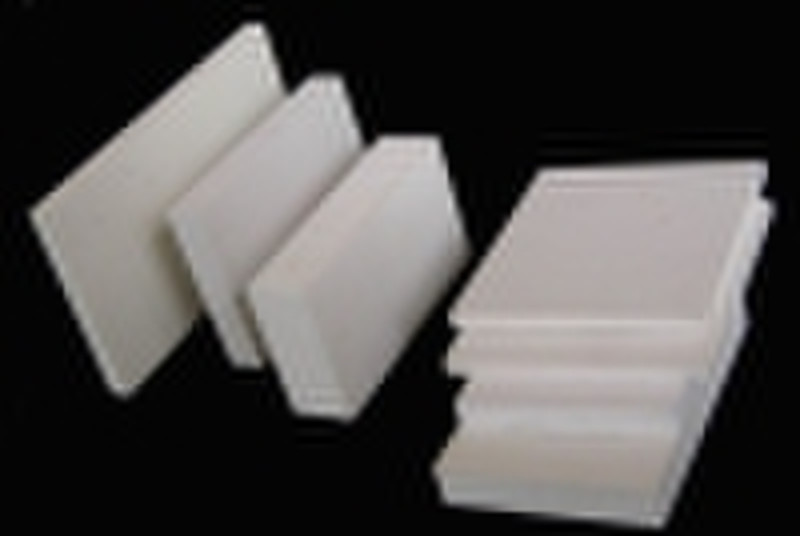

PVC geschäumte Bretter

original-Preis: 1 200 000 USD

Wuxi, China

Produktionskapazität:

4 Einstellen / Jahr

Zuming Tan

Kontaktperson

Basisdaten

PVC skinning foamed panel production line is launched by our company on the basis of wide investigation into users and application of advanced foreign technology. The whole production line is made up of specially designed extruder, die, and auxiliary machine, which can be applied into production of PVC skinning foamed panel at width of 1220mm, and thickness of 3-30mm.Products are made by our own extrusion lines. Steps of production process:1.Batching 2.high-speed mixing 3.Extrusion 4.Foaming 5.Cooling setting 6.Spraying 7.Hauling-off 8.Cutting 9.Stacking 10.Testing 11.Finished products into warehouse1. Extrusion system: using Parallel Twin-screw extruder SJSP130. The screws are well designed in accordance with the process, with high capacity and extrusion efficiency, material being uniformly sheared, 2. Die system: using runner structure specially designed for skinning foamed panel, which makes the extrusion and foaming of material more uniform. 3. Cooling setting system: compression panel structure, hydraulic control system, which makes controlling dimension of panel easily. Pipes of cooling system make the cooling of panel more uniformly and pitching faster. 4. Hauling-off and cutting system: cylinder-type combined hauling-off machine, which makes draft measurement easy. Synchronous electric control of cylinder-type hauling-off machine and broad cutting machine makes incision of panel flat.The whole line is fine in experience, and easy in operation. The panel made by our production line has its advantage of high foaming ratio, high surface hardness, flat and wear-resistant surface. Our company provides with our client material formulation and process techniques if they need.

Lieferbedingungen und Verpackung

Packaging Detail: Wooden case Delivery Detail: 120 days

Hafen: Shanghai

Zahlungsbedingungen

Telegraphic transfer

-

Zahlungsarten

Wir akzeptieren: