Katalog

-

Katalog

- Auto & Motorrad

- Bauwesen und Immobilien

- Bekleidung

- Büro- und Schulartikel

- Chemikalien

- Dienstleistungen für Unternehmen

- Eisenwaren

- Elektrische Geräte & Zubehöre

- Elektronische Bauteile

- Energie

- Galanteriewaren

- Geschenke und Kunsthandwerke

- Gesundheit und Medizin

- Gummi und Kunststoffe

- Haus und Garten

- Haushaltsgeräte

- Koffer, Taschen & Hüllen

- Landwirtschaft

- Lebensmittel und Getränke

- Licht und Beleuchtung

- Maschinen, Geräte und Werkzeuge

- Maschinenteile und Herstellung Dienstleistungen

- Messapparat und Analysegerät

- Mineralien und Metallurgie

- Möbel

- Schuhe und Accessoires

- Schönheit und Körperpflege

- Service Geräte und -Ausstattung

- Sicherheit und Schutz

- Spielzeuge und Hobbys

- Sport und Unterhaltung

- Telekommunikations

- Textil und Lederware

- Transport

- Uhren, Schmuck, Brillen

- Umweltschutz

- Unterhaltungselektronik

- Verpacken und Drucken

- Werkzeuge

- Überschüssiger Warenbestand, Lager

Filters

Search

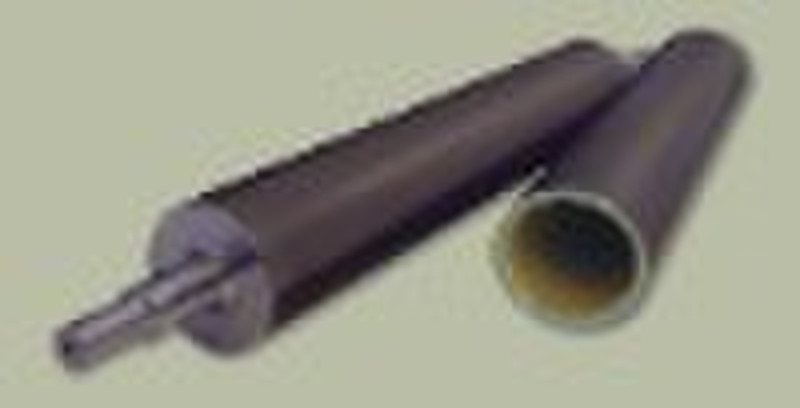

Laser gravierte Keramik-Anilox Teil

original-Preis: 350,00 USD

Shanghai, China

Kennan Hu

Kontaktperson

Basisdaten

| Ort der Herkunft | Shanghai China (Mainland) |

|---|---|

| Marke | Auclean |

Steel Base: High quality steel has been used to make steel base. Roll body use seamless steel pipe and both shaft use hammered steel 45Cr, compact welding after shrink on fit, relieving of internal stress, heat treatment and tempering, dynamic balancing, thus to make sure steel base fulfill the high requirement of laser engraved ceramic roller production process. Plasma Coating: High quality raw materials used for bonding (NiCr) and ceramic coatingFi (Cr2O3), this ensures adhesive strengthen between steel base and bonding layer, bonding layer and ceramic layer, extremely low porosity ceramic layer ensures good wear resistance. Finish with fine polishing by diamond polishing belt. Anilox Volume Measurement: Auclean use AniCAM to check cell volume precisely SHARP FORMAT Anilox Cel: Uniform cell shape Smooth cell wall Flat cell bottom High cell volume Easy for cleaning. Screen Line: Anilox screen line decided by plate screen line, normally screen line of anilox roll is 4-7 times of plate screen line. Do not use too high screen line unless necessary. At high screen line cell opening is very small and cell wall very thin, it requires higher ink fluidity. Flexo packaging printing normally use screen line from 360 to 1000 LPI. For corrugated printing from 200 to 450 LPI. Cell Volume: Cell volume is a range decided by screen line. BCM is international standard unit to describe cell volume. Optimal cell volume is the key part for high printing quality. Cell volume determination should be based on volume report and actual printing quality. We are ready to provide optimal solution for anilox roll selection and cell configuration based on our professional knowledge and experience. Banded anilox is the best way to select screen line and cell volume. We are ready to provide optimal solution for anilox roll selection and cell configuration based on our professional knowledge and experience.

Lieferbedingungen und Verpackung

Packaging Detail: wooden case Delivery Detail: 20 days after received the order

Zahlungsbedingungen

Telegraphic transfer

-

Zahlungsarten

Wir akzeptieren: