Katalog

-

Katalog

- Auto & Motorrad

- Bauwesen und Immobilien

- Bekleidung

- Büro- und Schulartikel

- Chemikalien

- Dienstleistungen für Unternehmen

- Eisenwaren

- Elektrische Geräte & Zubehöre

- Elektronische Bauteile

- Energie

- Galanteriewaren

- Geschenke und Kunsthandwerke

- Gesundheit und Medizin

- Gummi und Kunststoffe

- Haus und Garten

- Haushaltsgeräte

- Koffer, Taschen & Hüllen

- Landwirtschaft

- Lebensmittel und Getränke

- Licht und Beleuchtung

- Maschinen, Geräte und Werkzeuge

- Maschinenteile und Herstellung Dienstleistungen

- Messapparat und Analysegerät

- Mineralien und Metallurgie

- Möbel

- Schuhe und Accessoires

- Schönheit und Körperpflege

- Service Geräte und -Ausstattung

- Sicherheit und Schutz

- Spielzeuge und Hobbys

- Sport und Unterhaltung

- Telekommunikations

- Textil und Lederware

- Transport

- Uhren, Schmuck, Brillen

- Umweltschutz

- Unterhaltungselektronik

- Verpacken und Drucken

- Werkzeuge

- Überschüssiger Warenbestand, Lager

Filters

Search

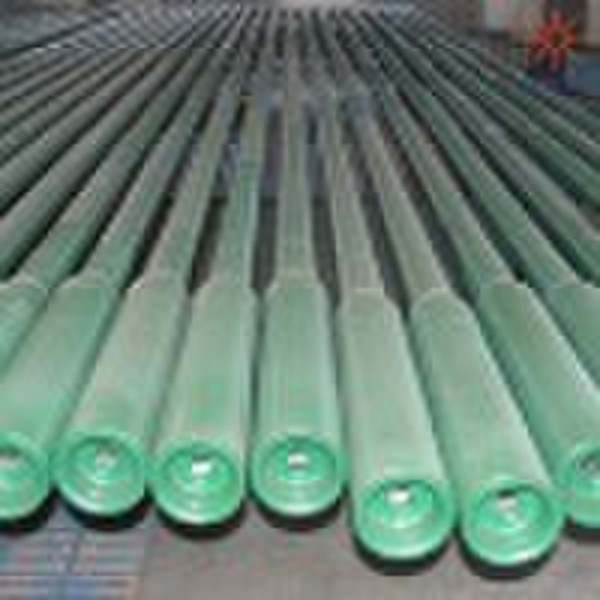

Heavy Weight Bohrrohr

yu li

Kontaktperson

Basisdaten

| Ort der Herkunft | Beijing China (Mainland) |

|---|---|

| Geben | Drill Pipe |

| Maschine Typ | Bohren Werkzeug |

| Material | Manganhartstahl |

| Verwenden | Brunnenbohrungen |

The heavy Weight Drill Pipe (HWDP) was developed to provide a gradual transition from the drill collars to the drill pipe. This HWDP helps to prevent stress concentration at the top of the drill collar. It also allow drilling at higher rpms, reducing torque and differential pressure sticking. The HWDP is intended primarily for directional drilling. As it bends easily, it simplifies directional control and minimizes connection fatigue problems common to high-angle or horizontal drilling. The reduced number of pipe failures and increased drill-stem service also make HWDP appropriate for some straight-hole applications. Various combinations of HWDP, drill collars, and standard drill string can be created to meet the challenge of severe drilling conditions. We can supply integral HWDP from 2-7/8” to 6-5/8”. Also we can supply friction welded HWDP, which is assembled with AISI 1340 steel pipe and AISI 4145H or 4137H tool joints. Theory 1. Hardbanding HWDP's wear resistance hardbanding is welded by an automatic machine after preheating the pipe and tool joints. Standard Bands: * one 4" wear band on both pin and box end, plus one 1" band on 18°shoulder of box. * two 3" wear bands on central upsets the hardbanding is completely flush on both tool joints and 1/8" oversize on the central upset(fully flush on request). The types of Hardbanding include Iron-Matrix powder alloy, Tungsten Carbide Sparticle, Arnco 100XT AND 300XT and TCS. 2. Internal Plastic Coating HWDP could be coated internally with DPC, TK 34 or TC2000 as customer's request, which are able to prevent corrosion and extend using time. 3. Initial Make up and Break out service The factory Make-up and Break-out services, which is the most important factor affecting the life of the connections, is regarded as an important element to greatly improve the efficiency on rig floor. The Controlled Make-up & Break-in procedures are consistently applied to every tool joint and ensure the connections quality. Suitable dope and correct toque value are essential for the Make-up & Break-in procedures. HWDP will supply perfect factory Make-up and Break-out services if order and inquiries Material we offers both integral and friction welded types of heavy weight drill pipes. The material of integral HWDP is manufactured from one piece of AISI 4145H solid bar, fully heat treated, all physical properties are conform with API Spec 7-1 latest edition. The welding HWDP is assembly by two pieces of tool joints and one piece of central pipe by inertial friction welding. The tool joints are manufactured from AISI 4145H or 4137H alloy steel and the central pipe is manufactured from AISI 1340 alloy steel. The mechanical and chemical property of tool joints and central pipe are conformity to API Spec 7-1 latest edition Rigid Inspection Procedures All HWDP are inspected to comply with API standards and our own internal specifications. These inspections include visual dimensional checks, ultrasonic inspections, chemical composition and mechanical properties tests. Cold rolled HWDP’ thread roots and stress relief features are cold rolled, which is helpful to reduce the fatigue failure of threads by minimizing crack initiation. Main parameters: No.TypeOutside diameter Inch(mm)Inner diameter inch(mm)Tool jointPipe body center wear padSingle Weight(kg)Connection TypeConnection O.D Inch(mm)Center(mm)End area(mm)1ZH-JZ55-5 1/2 FH-15 1/2(139.7)3 5/8(92.1)5 1/2 FH7(177.8)152.4144.57302ZH-JZ50-NC50-15(127)3(76.2)4 1/2 IF6 1/2(165.1)139.7130.27003ZH-JZ45-NC46-14 1/2(114.3)2 13/16(71.4)4 IF6 1/4127117.55854ZH-ZJ35-NC38-13 1/2(88.9)2 1/16(53.39)3 1/2 IF4 3/4(120.7)101.692.1370 Manufacturing Process:

Zahlungsbedingungen

Letter of credit

Telegraphic transfer

-

Zahlungsarten

Wir akzeptieren: