Katalog

-

Katalog

- Auto & Motorrad

- Bauwesen und Immobilien

- Bekleidung

- Büro- und Schulartikel

- Chemikalien

- Dienstleistungen für Unternehmen

- Eisenwaren

- Elektrische Geräte & Zubehöre

- Elektronische Bauteile

- Energie

- Galanteriewaren

- Geschenke und Kunsthandwerke

- Gesundheit und Medizin

- Gummi und Kunststoffe

- Haus und Garten

- Haushaltsgeräte

- Koffer, Taschen & Hüllen

- Landwirtschaft

- Lebensmittel und Getränke

- Licht und Beleuchtung

- Maschinen, Geräte und Werkzeuge

- Maschinenteile und Herstellung Dienstleistungen

- Messapparat und Analysegerät

- Mineralien und Metallurgie

- Möbel

- Schuhe und Accessoires

- Schönheit und Körperpflege

- Service Geräte und -Ausstattung

- Sicherheit und Schutz

- Spielzeuge und Hobbys

- Sport und Unterhaltung

- Telekommunikations

- Textil und Lederware

- Transport

- Uhren, Schmuck, Brillen

- Umweltschutz

- Unterhaltungselektronik

- Verpacken und Drucken

- Werkzeuge

- Überschüssiger Warenbestand, Lager

Filters

Search

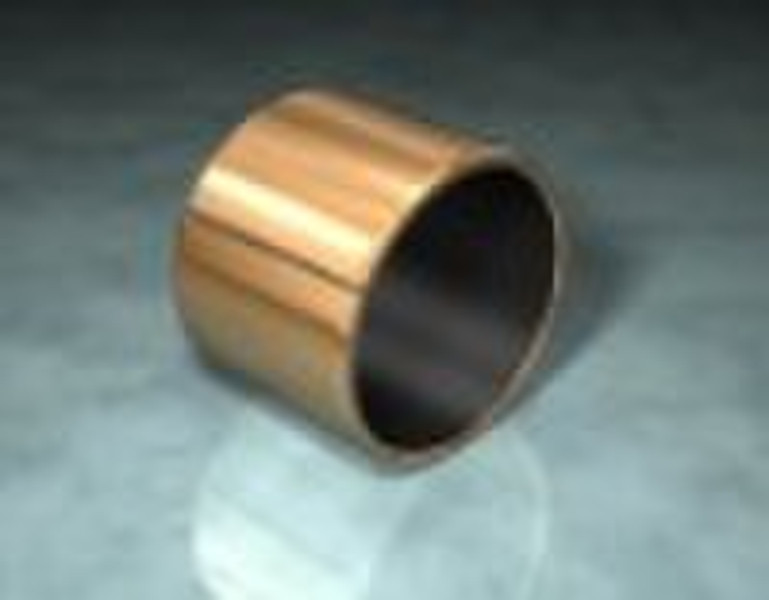

Bronze Matrix Schmierbuchse

original-Preis: 1,00 USD

Jiaxing, China

Produktionskapazität:

10000 Stück / Tag

li zhongcheng

Kontaktperson

Basisdaten

| Geben | Flansch |

|---|---|

| Ort der Herkunft | Zhejiang China (Mainland) |

| Marke | CDB |

| Modell-Nummer | SF-1B |

| Material | Cu |

SF - 1B bronze foundation bearing, is the tin bronze body and sintering spherical powder, bronze among surface rolling PTEE and high temperature resistant filling materials and into. It has high safety coefficient in successive work can't stop repair venues and high temperature cannot refueling places special apply. Presently it is widely used in metallurgical steel industry, casting billet groove, GaoWenLu before furnace equipment, cement grout pump and screw conveyor. It can be in external composite steel set, also can be made into flanging, achieve devicees, inner pore also friction use effect. Bridge bearings sliding parts, which adopts SF - 1B wear-resisting layer thickening products to replace the pure PTFE board, achieve 130N/mm2 axle load use requirements. Technical parameters The maximum load pressure: 140N/mm2 Applicable temperature range: - 195 + 300 degrees Celsius Maximum sliding speed: was/s Friction coefficient: 0.03 0.18 Allow the highest PV value (dry) : 4.3 N/mm2. J m/s Allow the highest PV value (oil) : 50N/mm2. J m/s Application characteristics: 1, PTFE, lead the mixture in the sports can form good transfer membrane protection on grinding axis. 2 and sintering layer and the copper substrate has good thermal conductivity, can rapid transfer process of heat generation. 3, copper has lubricating and can be used for long-term operation and cannot stop overhaul of parts. 4, base copper has good corrosion resistance and can be used for weak acid, alkali occasion. 5, has the good carrying capacity. 6, the products have been widely used in metallurgical steel industry, GaoWenLu steel ring parts and cement grout pump, spiral conveyer, port Machinery and shipping machinery cork. 7, can be in external composite steel sets, Or made into flanging, achieve in the hole and face to be used at the same time effect. SF - 1B series chemical characteristics Bearing type vacuum in water vapor in the air in dilute acid in alkaline acid solution SF - 1B good good good good in no no good MMD - 10 friction and wear test Model test time test conditions friction coefficient final temperature (degrees Celsius) eventually wear allowance (mm) Lubrication speed pressure SF 3hr dry 0.4-1B m/s 3.5 N/mm2 anti-frost 0.151 83 SF - 1B 3hr oil 0.4 m/s 3.5 N/mm2 0.058 55 0.

Lieferbedingungen und Verpackung

Packaging Detail: Neutral packing and size can to orders Delivery Detail: According to the specific circumstances and decide

Hafen: shanghai

Zahlungsbedingungen

Letter of credit

Telegraphic transfer

-

Zahlungsarten

Wir akzeptieren: