Vacuum Insulation Panel

原价: 3,00 USD

厦门市, 中国

生产能力:

10000 片 / Day

Hardy Lou

联系人姓名

基本信息

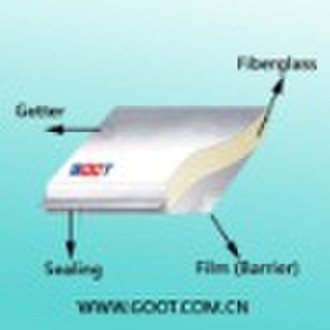

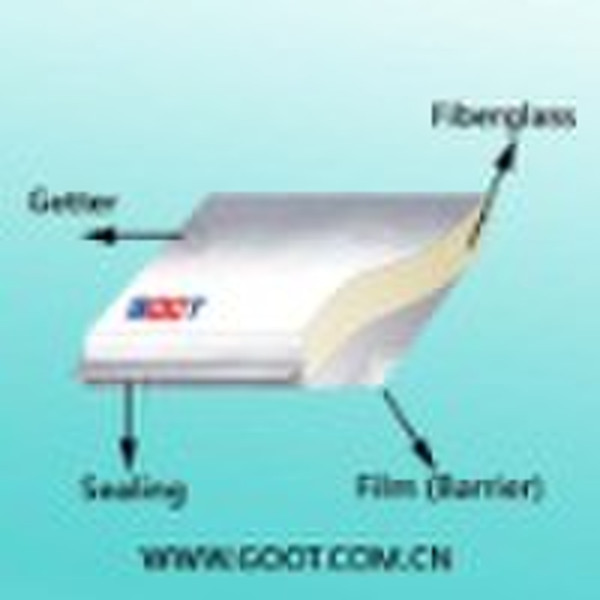

Vacuum Insulation Panel (VIP) is a new highly-efficient thermal insulation product which takes fiberglass as the core material. The VIP's are constructed using a special technique by inserting the open-celled filler into a centralized sealed barrier. Using the core material which provides the structural strength and resistance for heat exchange making the VIP extremely efficient in low thermal conductivity that has less than 0.004w/m. K. The VIP has been proven to exceed its performance than the conventional insulations by far. Vacuum Insulation panels are our new high- efficient thermal insulation. It is created by inserting the open celled filler into a centralized sealed barrier. The core material provides the structural strength and resistance to heat transfer.Applications: Cold insulated equipments of different industries Shipping containers Spaceflight/ Aviation Communication/ transportation Medical Refrigerators and freezers Marine and recreational refrigeration vehicles Civil refrigeration equipment Insulation for constructionAdvantages: 7- 10 times better insulation value then conventional insulations Thin wall, small volume, lightweight Extremely low thermal conductivity 0.004w/m. K Resistance to heat transfer among the gas molecules Non-ODS material Not harmful for the environment Meets all insulating requirementsSpecification: 1) Compressive Strength: 0.14MPa - 0.25MPa 2) Thickness: 10 - 35mm 3) Maximum Dimensions: 1600 x 700 x 35mm 4) Core Material: Superfine fibreglass 5) Thermal Conductivity: Less than 4mw/m. K(under standard environmental condition: Ambient temperature 24degree centigrade, relative humidity 50%) 6) Density: About 230kg/m3 7) Internal Pressure: 0.1Pa 8) Operating Ambient: -50 70 degree centigrade 9) External Tolerance of VIP: 1mm 10) Packing: Carton with foam and air bubble film 11) Service life: 10-15 years under standard environmental condition

交货条款及包装

Packaging Detail: Paper Carton Delivery Detail: Within 21 days

端口: Xiamen

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: