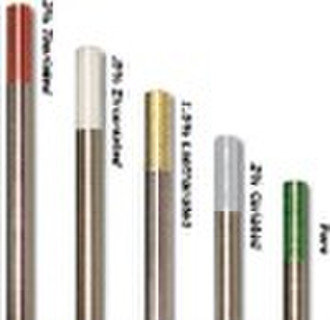

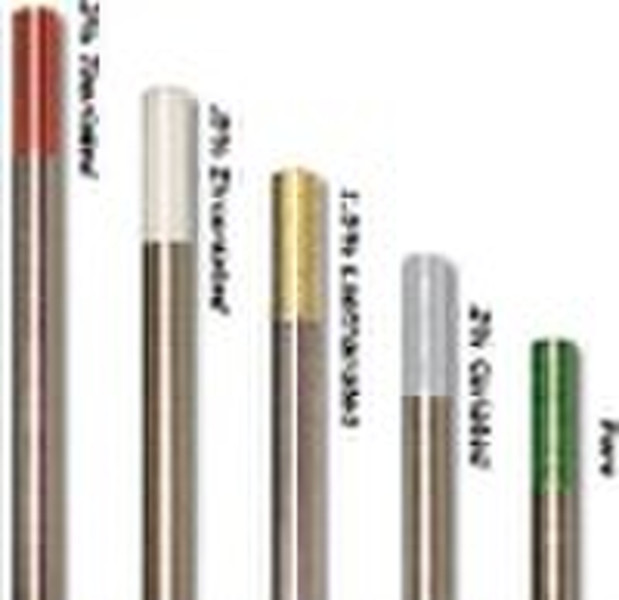

tungsten electrode

原价: 40,00 USD

株洲 市, 中国

生产能力:

300 吨 / 年

david dai

联系人姓名

基本信息

tungsten electrodeCeriated TungstenElectrodes Characteristics: Ceriated Tungsten is a non-radioactive material. It is known to be especially good for DC welding with low amperage because it starts very easily at low amps and usually requires about 10% less amps to operate than thoriated material. It is very popular to be used for the welding of orbital tube, pipe, very small parts, short welding cycles and also where a specific number of welds are called and then the electrode is to be replaced. DesignationOxide AdditiveImpurities Content%Tungsten Content%Color SignCategoryContent%WC20CeO21.8-2.2<0.20BalanceGrey Thoriated TungstenElectrodes Characteristics: Thoriated Tungsten is the most commonly used tungsten in America and some other countries and is a good general use tungsten. Especially, it performs well when overloaded with extra amperage. However,since it is a low-level radioactive hazard many users have switched to other alternatives. This tungsten is used primarily for DC welding of carbon & stainless steels, nickel alloys and titanium,etc. DesignationOxide AdditiveImpurities Content%Tungsten Content%Color SignCategoryContent%WT10ThO20.80-1.2<0.20BalanceYellowWT20ThO21.70-2.20<0.20BalanceRedWT30ThO22.80-3.20<0.20BalanceVioletWT40ThO23.80-4.20<0.20BalanceOrange Lanthanated Tungsten Characteristics: Lanthanated Tungsten is a non-radioactive material with good welding performance. Its electric conductivity is most closed to that of 2% Thoriated Tungsten. Welders can easily replace Thoriated Tungsten Electrodes with Lanthanated without any changes of welding program. In Europe and Japan, Lathanated Tungsten has been the most popular alternative to 2% Thoriated Tungsten for most applications. This tungsten is used primarily for DC welding but will also show good results for AC welding. DesignationOxide AdditiveImpurities Content%Tungsten Content%Color SignCategoryContent%WL10La2O30.8-1.2<0.20BalanceBlackWL15La2O31.3-1.7<0.20BalanceGolden yellowWL20La2O31.8--2.2<0.20BalanceSky blue •provide all kinds of tungsten electrode according to customer's drawing and requirements

交货条款及包装

Packaging Detail: packing in standard iron drums Delivery Detail: 20 days

端口: shang hai

付款条款

Telegraphic transfer

-

支付方式

我们接受: