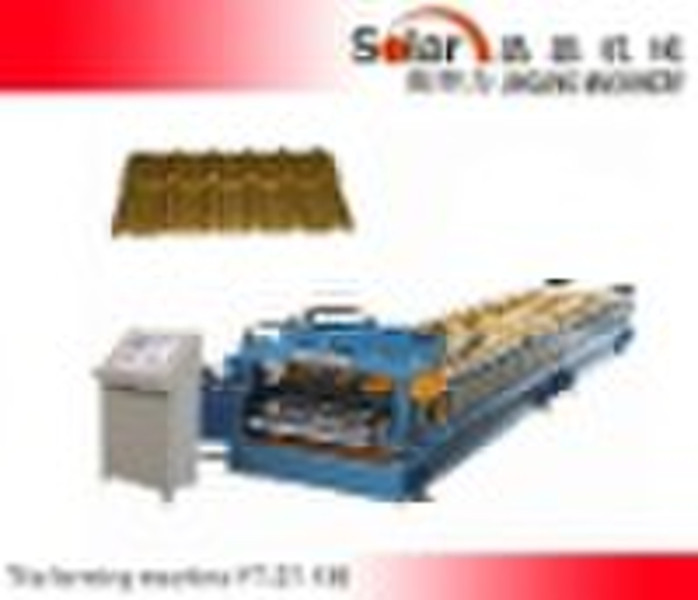

steel tile roll forming machine

原价: 25 000 USD

杭州市, 中国

生产能力:

20 片 / 月

Frank Bao

联系人姓名

基本信息

Steel Tile Roll Forming Machine Feature: The colored steel tiles produced by roof tile forming machine look beautiful, elegant and noble. They are widely used as the roof of garden, factory, hotel, exhibition center and villa, etc. Steel Tile Roll Forming Machine components: Roof tile forming machine consists of uncoiler, coil sheet guiding device, covering film device, main roll forming system, pressing device, cutting device, Hydraulic station, PLC control system and support table... Steel Tile Roll Forming Machine technical parameters: 1. Suitable material: Color steel sheet 2. Thickness of raw material: 0.5-0.6mm 3. Yield strength of material: 235Mpa 4. Working speed: About 2-4m/min(Better For option) 5. Step distance: Adjustable according to requirement (>=250mm) 6. Power Requirement Main motor power: 5.5 Kw(Depend on final design) Hydraulic station power: 2.2Kw(Depend on final design) 7. Uncoiler's loading capacity Max. Capacity: 5000kgs (can be increased to be 10T) 8. Controlling system: Mitsubishi PLC & converter 9. Machine's size: About 18m*1.5m*1.4m (Depend on final design) 10. Machine with CE certificate. Steel Tile Roll Forming Machine Material of Main EquipmentsRoller Material: High grade No.45 forged steel, with digital-controlled procession, Plated with hard chrome.Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaftElectric Elements: PLC control panel, Transducer and touching screenimported from Mitsubishi of Japan. Other elements from famous suppliers in ChinaCutter blade: Cr12 mould steel with quenched treatmentMotors and hydraulic valves: Famous suppliers in China.

交货条款及包装

Packaging Detail: Container packing of the line suitable for overseas shipping,Package style: Naked and covered by plastic film, spare parts and some small parts packed in wooden box. Delivery Detail: 50 days

端口: Shanghai

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: