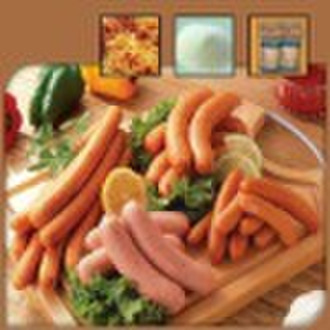

Sausage-type Carrageenan for Meat Manufacturing

Annie Yang

联系人姓名

基本信息

Sausage-type Carrageenan (Type: RP-301, RP-302) This type of carrageenan is to improve thickening, emusifying and water-keeping of minced meat, and increase elasticity and toughness of meat product. Product Characteristics: The meat carrageenan RP-301 is made of semi-refined carrageenan, compounded with other natural gum, which is usually used for high-class Sausage-type meat prodution. It has a well combination with protein, starch and other accessories and excellent water-keeping It suits for the requirement of sausage and emulsification , with a effective result of increasing elasticity and taste. The meat carrageenan RP-302 is made of semi-refined carrageenan, compounded with other natural gum. It has a higher cost-effective with a strong cooperativity with strach, soybean protein isolate, meat and other organics. It suits for the low-end market . Reference Formula: Carrageenan RP-301, RP-302: 0.5-1%; Lean Meat: 45%; Fatty Meat: 18%; Compound Phosphate: 0.5%; Starch: 6%; Soybean Protein Isolate: 2%; Salt: 0.6%; Spice: 0.5%; Sodium Nitrite: 0.05%; Add water to 100% Method of Application: Put the lean meat into the chopping machine by 3 to 5 roll with low speed. Meanwhile add salt, sodium nitrite, compound phosphate and 1/3 ice water into the machine. The chopping is no less than 5 minutes. Then add the fatty meat or other accessories to chop for almost 5 minutes. Add 1/3 ice water and spice to chop for 4 minutes, and add carrageenan, strach, soybean protein isolate and the remaining ice water to chop for 5 minutes. The temperature should control to be almost 12°C for the emulsification meat. The dosage of this carrageenan is 0.5%-1% of the total amount of meat.

交货条款及包装

Packaging Detail: 25Kg/Bag,packed in strong kraft paper bag Delivery Detail: 25 days

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: