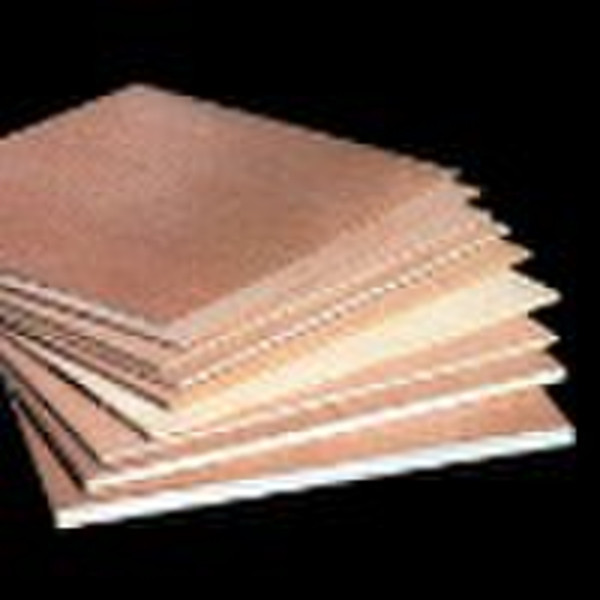

Low Price Veneer Plywood

Bihai Li

联系人姓名

基本信息

Product: film faced plywood (shuttering plywood) Core: poplar, birch, hardwood, pine, and combination (mixed) Layer: 9 to 13 layers Glue: WBP (phenolic glue) PSF: black or brown, 120 to 240g/m² Surface type: smooth/anti-slip Size: 1,220 x 2,440mm/1,250 x 2,500mm Thickness: 9 to 27mm Density: Poplar: 550kg/m³ Birch: 720kg/m³ Pine: 500kg/m³ Combination: 680kg/m³ Advantages: Lightweight;better be used for high building and bridge construction Large extent: the largest extent is 1,250 x 2,500mm, reduce the juncture in order to improve thework efficiency No warp, no distortion, no cleft, well water-resistant, long-playing used, and recycled Easy doff the film, 1/7 of the steel film Do concrete: beautiful and slippy surface, take out the second plaster, which can save 30% working times Cauterization-resistant; The concrete surface with no polluting Well heat preservation, in favor of winter construction.Do the plyform that can bend the plane Well construction capability Excelled bamboo plywood and armor plate on nailing, sawing, boring, and more. It could be processed to various forms according to construction requirements Packing: inside is plastic sack, the outside are made of 3mm thickness plywood .

交货条款及包装

Packaging Detail: Pallets are coverd with plywood or carton and them steel for strength Delivery Detail: within 20-30days after deposit reaches us

付款条款

Documents Against Payment

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: