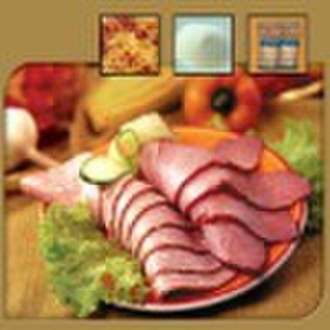

Injection-type Carrageenan for Meat Manufacturing

Annie Yang

联系人姓名

基本信息

Injection-type Carrageenan (Type: RP-101, RP-102) For the meat products of injection technology, such as barbecues, spiced pork, ham and other meat products. For the purpose of increasing tenderness, production yield and holding the flavour., carrageenan should be dispersed into the brine, then injected into the meat by hypodermic needles, and can be distributed into the inner structure of meat evenly. Product Characteristics: The meat carrageenan RP-101 is made of refined carrageenan, compounded with other natural gum.With features as excellent water-keeping, good dispersion in brine and high transparency, the injection-type carrageenan is moderate in price and widely applied in the market. The meat product produced from this carrageenan has high production yield, smooth cutting and moderate taste. The meat carrageenan RP-102 is made of semi-refined carrageenan, compounded with other natural gum and has a very high cost-effective. Reference Formula: Carrageenan RP-101, RP-102: 2-3%; Salt: 10-12%; Sodium Erythorbate: 0.08%; Compound Phosphate: 20-25%; Soybean Protein Isolate: 2%; Sodium Nitrite: 0.05-0.07%; Sugar: 2.5-3.0%; Monosodium Glutamate: 0.2-0.4%; Add water to 100% Method of Application: Brine should be prepared 24 hours before the injection. Dissolve the phosphate into a small amount of hot water, then add some salt and water for mixing. Add sugar and monosodium glutamate and mix the liquid evenly, then the liquid should be preserved by cold storage at 4°C. Add sodium erythorbate, sodium nitrite, soybean protein isolate and carrageenan one hour before use, mix the liquid completely and filtration for using. The using ratio of lean meat to injection liquid is 100 : 23.

交货条款及包装

Packaging Detail: 25Kg/Bag,packed in strong kraft paper bag Delivery Detail: 25 days

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: