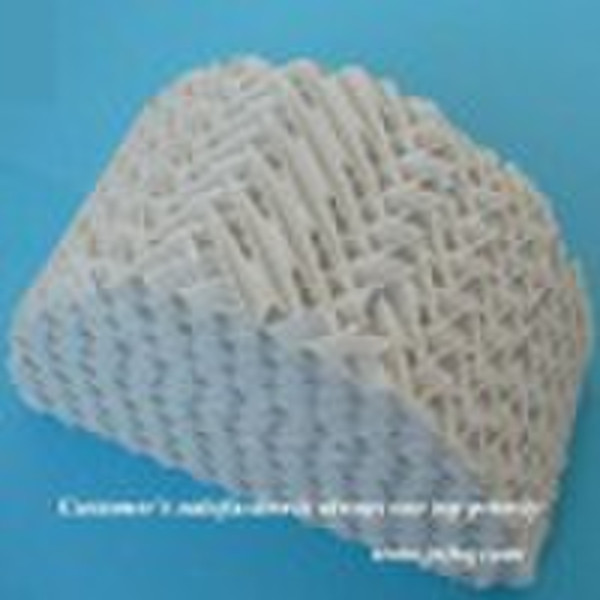

Ceramic Structured Packing

Yat Hu

联系人姓名

基本信息

| 出生地 | Jiangxi |

|---|---|

| 牌子的名字 | HQ |

The Ceramic Structured Packing has the advantages of 1000 or above). It is flexible in operation and without amplification effect in a large tower, and particularly suitable for the rectification and absorption of corrosive mixture on the occasion of strict requirements of pressure drop and number of theoretical plates.Physical & Chemical properties Acid resistance:≥99.8% Thermal resistance:≥1000 Mohs' hardness scal:≥7 Crushing strength:≥2.0MPa Characteristic Indexes of Ceramic Structured PackingsType Surface areaVoid fractionBulk density Wave height Wave spanThicknessNtMax.F-factor P UNIT m2/m3%kg/m3 mmmmmmm-1m/s.(kg/m3)0.5 Pa/m 45045075520-5506.0±0.512±0.51.0-1.33-41.8-2.0200-25040040076500-5207.0±0.514±0.51.0-1.32.8-3.22.0-2.2180-26035035078480-5208.0±0.516±0.51.2-1.52.5-2.82.2-2.6200-26025025082420-45011.0±0.522±0.51.2-1.52.3-2.52.6-2.8220-28016016086350-38017.0±0.534±0.51.5-2.01.8-2.02.8-3.0250-30012512587300-35023.0±0.542±0.52.0-2.51.5-1.83.0-3.2280-35010010090220-25030.0±0.550±0.52.0-2.513.5250-300 The ceramic structured packing has the types of 100-750X/Y, X and Y respectively represents the wave angle are 30° 45°, and the number means the value of surface. The diameter can be manufactured in 100-8000mm, if upon request, it can also be designed and manufactured to meet the need of specific applications.

交货条款及包装

端口: Shenzhen

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: