Cast Tungsten Carbide

billy cho

联系人姓名

基本信息

| 出生地 | Jiangsu China (Mainland) |

|---|---|

| 牌子的名字 | MAOYUAN |

| 模式的数量 | YZ5-10f |

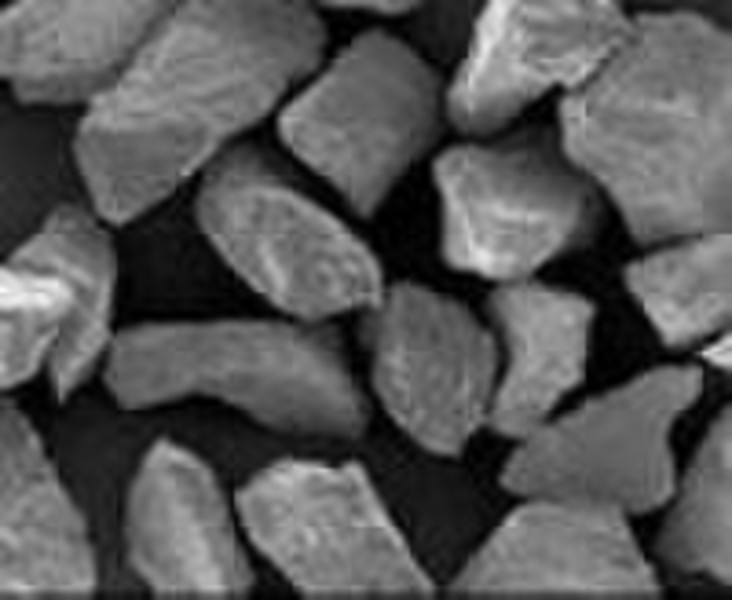

Metal tungsten and tungsten carbide powders as raw materials are mixed,packed in a graphite boat, melted in a melting furnace at about 3000oC,and held for a certain time to obtain alloy casting block of cast tungsten carbide with phase diagram of W2C and WC and particle size of 1-3µm. Particle are silver grey with metal luster. Cast tungsten carbide is applied by oxygenace-tylene flame,arc,spray, braze and wet welding on wear places.It is also adhered firmly to the surface of wear work pieces with epcxy resin and inorganic additives at lower temperature and impact.The parts of build-up cast tungsten carbide coating can stand with high temperature and impact.It is characterized by long tool life,easy maintenance,low coat and improved productivity. In the production,whether equipment normally run is dependent on materials wear resistance for wear parts in great degree.Selection of materials with better wear resistance provides longer equipment-life and stable running. Cast tungsten carbide as a wear material is widely used in the mining,petroeum,construction and agricultural machinery and steel industry etc.because of its high hardness (HRA 93.0 93.7),good wear resistance,easy build-up welding and low cost. Melting Point(oC): 2525 Density (g/cm3 ):16.5 Microhardness (kg/mm2 ): 2500-3000 Hardness(HRA): 93.0-93.7 Type and Partical SizesType

交货条款及包装

Packaging Detail: Drums Delivery Detail: 30 days

端口: nanjing

付款条款

Documents Against Acceptance

Documents Against Payment

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: