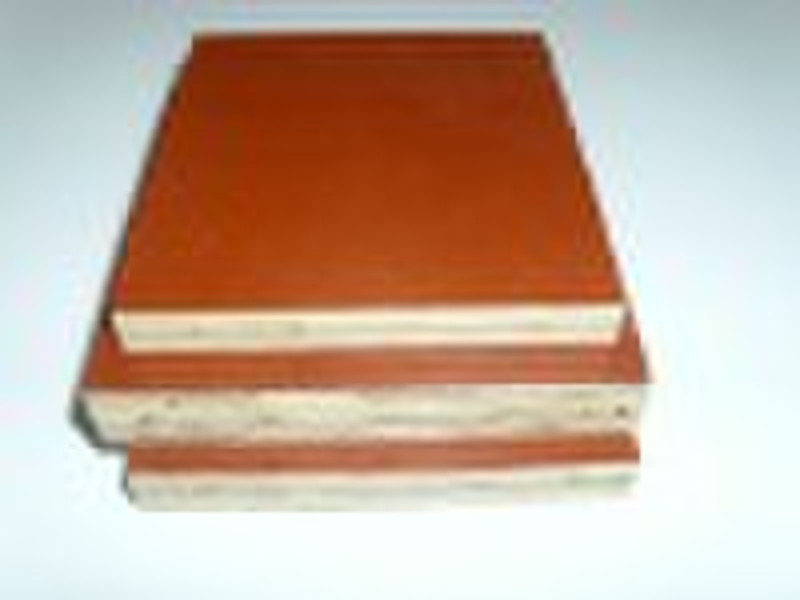

Bamboo concrete form panel

原价: 10,00 USD

中国

生产能力:

500 片 / Day

Elle li

联系人姓名

基本信息

Bamboo Concrete form panel also named Bamboo plywood, Bamboo Pane, Bamboo- Glued. The Bamboo Concrete Form Panel mainly made from bamboo, it is a new-style formwork as construction material, which is made after a series of mechanical and chemical processes, added measurable glue, and machined by one-time compound hotpressing technology. It contains the advantages as the following: 1. High strength, good tenacity, static camber of the formwork is about 4-5 times harder than the wood-glued board, this will be able to reduce the consumption of the formworks supporting in practice. 2. Wider width, less patching joint( 3 M2/pc), the square equals to the 6. 6 pcs of steel formworks at 15. M x 3M, faster formwork supporting and removing job. The expenditure is 1-2 times less than the normal steel formwork and wood formwork. 3. Glossy surface, easy for formwork removing job, smooth concrete surface, these will bring you a fast construction schedule to the project and make less cost. 4. Fine waterproof performance, the adhensive will not come unglued after water boiling, no deformation when be affected with water and damp, indubitable antisepsis and mothproof. 5. Thermal coefficient of the formwork is 0. 14-0. 16 W/M. MO, which is much less than the steel formwork, this is propitious to heat preservation during winter construction work. 6. High turnover of the formwork due to the both sides utilizing; Currently the turnover can be over 30 times under civilized using and proper storage. The bamboo- Glued formwork has wide purposes, it is fit for the horizontal or vertical formwork etc, for high-rise, extempore-pouring concrete wall, floor slab, viaduct, cloverleaf junction, main dam, tunnel and beam column construction. Our traditonal specifications is 4'x8'x10 15mm, 1000 x 2000 x 10 15mm Re: Bamboo Concrete Form Panel: A). Both sizes with wood+special paper film surface (Wood is poplar) We suggest to use Ship Board, Building Construction, Bridge which the concrete surface need more smooth and flat B). Both sizes with special paper film surface We suggest to use Container board, building construction. C). No film surface both sizes We suggest to use C grade, which is not strictly requirements in the surface conditions.

交货条款及包装

Packaging Detail: NUDE PACKING Delivery Detail: 10days for one 20 GP container after receiving L/C or deposit

端口: SHANGHAI

付款条款

Letter of credit

Telegraphic transfer

Western Union

-

支付方式

我们接受: