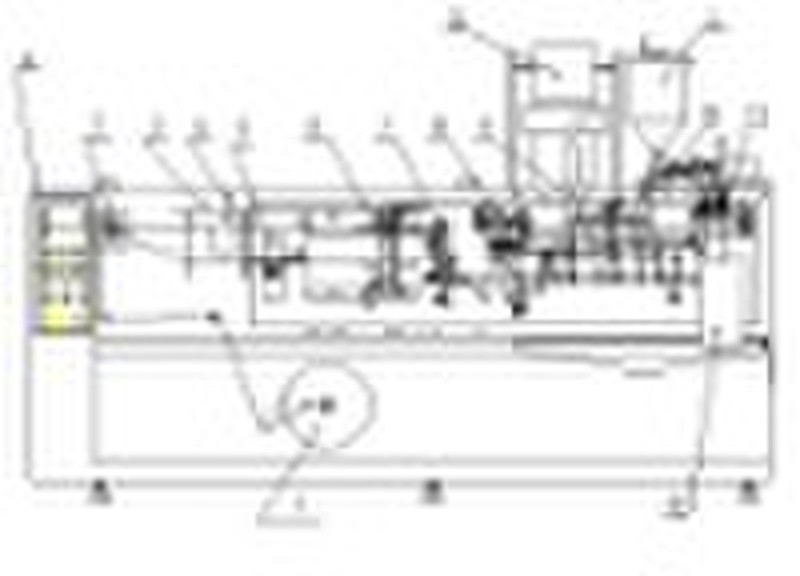

Alcohol Swabstick FFS Horizontal Packaging Machine

Forester Shine

联系人姓名

基本信息

Alcohol Swabstick FFS Horizontal Packaging Machinery Packaging Process Description: Process: Swabstick Storage Tank - Elevator Vibration Plate Filler -Linear Feeder Feeding - Manipulator Gripper - Form Pouch - Manipulator Gripper Feedingg into Pouch - Micro-filling Machine Filling Alcohol - Sealing Pouch Description: Elevator: To feed swabstick which put in storage tank upgrad to vibration plate filler. Vibration Plate Filler: To arrange the swabstick for head-organization orderly arrang into a straight line after transfer to the feeder, then linear feeder arrang swabstick. Manipulator gripper: Conveyor transport the swabstick to the position, then steer the swabstick erected, at last the manipulator gripper grip the swabstick after receiving the signal. Forming pouch: Packaging machine to form film into bag, transportinstitution send pouch cotton to the position of the gripper Manipulator feeding into pouch: To work downward, grip swabstick into pouch and loose it, then gripper upward movement for the next feeding Micro-filling machine filling Alcohol: To transport pouch which has put the swabstick to filling positions, then micro- filling machine fill the pouch with alcohol. Sealing Pouch: To sealing pouch which has swabstick and alcohol to complete thepackaging process Technical Parameer: Pouch Width 40mm90mm Pouch Length80mm205mm Volume 110m Speed 80-120 pouch/min. Packaging Film: Complex film Accuracy < ±0.2ml Reel 500mm Electricity Consumption4.5KW Power supply 3phase 380V 60HZ Air Consumption0.5m3/min Weight1250KG Size (L×W×H) 3900mm×970mm×2430mm

交货条款及包装

Packaging Detail: Wooden Case Delivery Detail: 70 days

端口: Shanghai

付款条款

Letter of credit

Telegraphic transfer

-

支付方式

我们接受: