Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

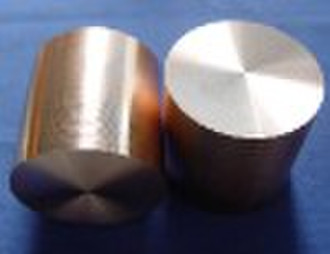

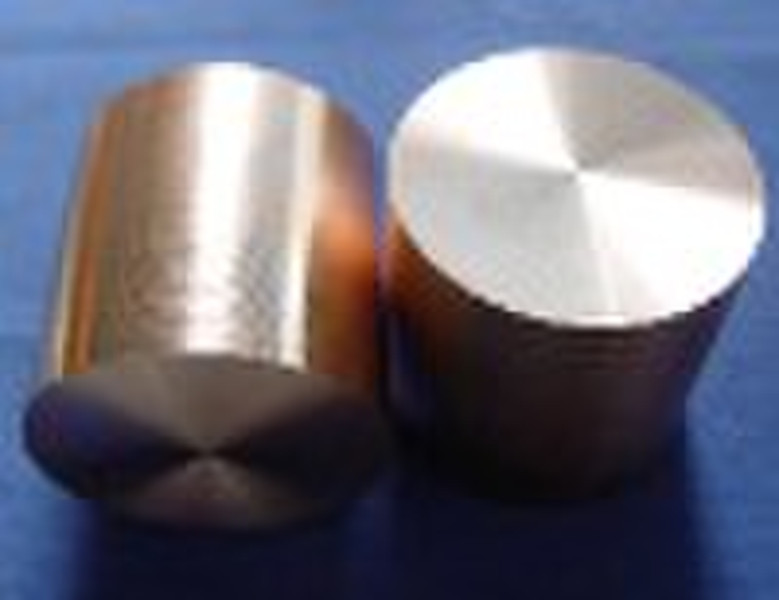

Вольфрам медный сплав стержня

ориг. цена: 20,00 USD

Китай

Leon Yan

Контактное лицо

Основные данные

| Место происхождения | Shaanxi China (Mainland) |

|---|---|

| Стандарт | Copper tungsten |

| Медь (min) | 10% |

| Номер Модели | SL |

| Сплав | Сплав |

Tungsten Copper alloy sheetThe alloy composed by tungsten and copper. The common content of copper in the alloy was 10% 50%. It was made by powder metallurgy, with very good thermal conductivity, electrical conductivity, good elevated temperature strength and a certain degree of plasticity. Under the very high temperatures conditions, such as the above 3000 , the element copper in the alloy has been liquefied natural evaporation, substantial absorption of heat, reduce surface temperature of material, therefore, such material is also known as metallic sweating materials. W-Cu alloy have a wide range of uses, mainly used to produce contacts of anti-high-voltage electrical arc ablation switch and rocket nozzle throat lining, tail vane and other high-temperature components, also used as EDM electrode, high temperature moulds, other use which required electrical conductive, thermal conductive performance and used in the situation of high temperature. Grade: CuW, RWMA Class 10, RWMA Class 11, RWMA Class 12 W-Cu using isostatic pressing - high-temperature sintering tungsten skeleton - soluble copper infiltration process, is an alloy of tungsten and copper 1.resistance welding electrode Combines the advantages of tungsten and copper, high temperature resistance, electric arc ablation resistance, high strength, high density, good conductivity of thermal and electric, easy to machining, and has the feature sweatcooling. Due to the feature of tungsten such as high hardness, high melting point, anti-adhesion, it often used to do the projection welding and butt welding electrodes which have a certain wear resistance and anti-high temperature performance. 2.Electrical spark electrode: When produce die need to corrosion and material is tungsten steel and high temperature super-hard alloy, the common electrode wearing heavy and rate slow. The W-Cu high electrical corrosion rate, low attrition rate, accurate electrode shape, excellent processing performance, can ensure the great improving of definition for the work piece. 3.High-voltage discharge tube electrode: When high-voltage vacuum discharge tubes working, temperature of contact material will increase thousands of degrees Celsius within of few split seconds.The high resistance to ablation performance, high toughness, good electrical and thermal conductivity of W-Cu can provide the necessary conditions for the stability work of discharge tubes. 4.Electronics packaging material: It have low-expansion characteristics of tungsten, but also has high thermal conductivity properties of copper, its thermal expansion coefficient and conductivity of thermal & electric can be changed by adjusting the ingredients, thereby facilitating the use of materials. Specifications of WCu Alloy: Code No.Chemical Composition %Mechanical propertiesCUImpurity WDensity (g/cm3 )Hardness HBRES( cm)Conductivity IACS/ %TRS/ MpaCuW(50)50+2.00.5Balance11.851153.254CuW(55)45+ 2.00.5Balance12.301253.549CuW(60)40+2.00.5Balance12.751403.747CuW(65)35+2.00.5Balance13.301553.944CuW(70)30+2.00.5Balance13.801754.142790CuW(75)25+2.00.5Balance14.501954.538885CuW(80)20+2.00.5Balance15.152205.034980CuW(85)15+2.00.5Balance15.902405.7301080CuW(90)10+2.00.5Balance16.752606.5271160

Условия поставки и упаковка

Packaging Detail: according to requirements Delivery Detail: 1 25days

Порт: Tianjin or Shanghai

Условия оплаты

Документы за наличный расчёт

Аккредитив

Электронный перевод

Вестерн Юнион

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: