Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

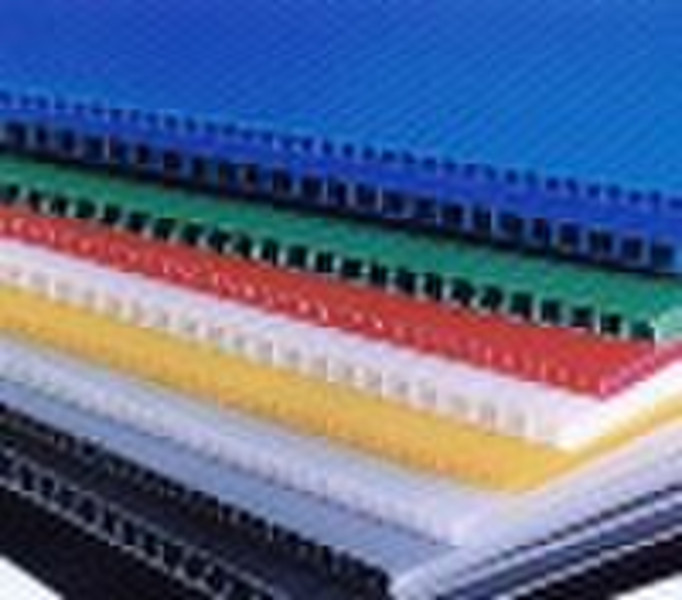

ПП Гофрокартон / ПП Твин стены доска

ориг. цена: 2,00 USD

Шанхай, Китай

Francis Xu

Контактное лицо

Основные данные

| Место происхождения | Shanghai China (Mainland) |

|---|---|

| Бренд | Osign |

| Номер Модели | OP |

| Толщина | 1-12mm |

| Материал | PS (Полистирол) |

PP corrugated sheet is made of blended PP copolymer and extruded in monoblock. It features flat, smoothness, light-weight, durability, and high-impact, anti-frost and chemical resistance. The most important property of PP board is that it meets the requirements of environmental protection because it is made of the compound of carbon and hydrogen, fire-retardant, toxic-free and can be recycled, reused and reduced. The thickness of current products are 2,3,4,5,6,7,8,9,10,11,12mm and with over ten different colors for choices. In addition, electric conduction or anti-staic agent can be added to be electric conductive or anti-static. Anti-ultraviolet agent can also be added to make the board anti-aging, weather-proof material. Application of PP Corrugated Sheets: 1. For buffer/protection The hollow structured of PP corrugated sheet and its impact-proof, compression resistant characteristic is suitable for bending, folding and packing. It is suitable for packing electronic products, steel roll, steel rope, wire or automobile, spare parts. In addition, its water/grease-proof, anti-chemical characteristic has made it an inevitable material for building. 2. For transportation/Packing The toughness and hollow structure of PP corrugated sheet can easily be beat and cut. It can be designed as all kinds of transportation box, mailbox, display rack, partition, etc. If you use well electric conduction or anti-static material, it will fully stabilize electric resistance. The characteristic of lightweight but born heavy is best for packing. 3. For display/advertisement The surface of PP corrugated sheet is smooth and flat, after corona treatment makes it good for printing. The print effect is excellent. it is water/heat-proof suitable for indoor/outdoor display board/advertisement. Performance: Item Unit Thickness & Physical Performance Parameter 2 3 4 5 6 7 8 9 10 11 12 Gram Weight G/M2 400- 400- 700- 800- 1200- 1400- 1600- 1800- 2000- 2100- 2200- Tension Fracture N ≥200 ≥250 ≥300 ≥350 ≥400 ≥450 ≥500 ≥550 ≥600 ≥700 ≥800 Elongation at Break % ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 ≥50 Horizontal Compression N ≥700 ≥900 ≥1000 ≥2500 ≥3000 ≥3500 ≥4000 ≥4500 ≥5000 ≥6000 ≥7000 Vertical Compression N ≥90 ≥150 ≥350 ≥600 ≥600 ≥700 ≥750 ≥800 ≥1000 ≥1100 ≥1200 Tearing Force N ≥50 ≥60 ≥70 ≥80 ≥100 ≥150 ≥150 ≥180 ≥210 ≥240 ≥270

Условия поставки и упаковка

Packaging Detail: carton, hard tube, pallet Delivery Detail: 15 days

Порт: shang hai

Условия оплаты

Аккредитив

Электронный перевод

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: