Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

Лифт веревка с ядром стали армированного (Se

Edwin Ren

Контактное лицо

Основные данные

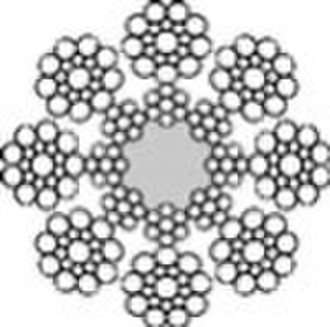

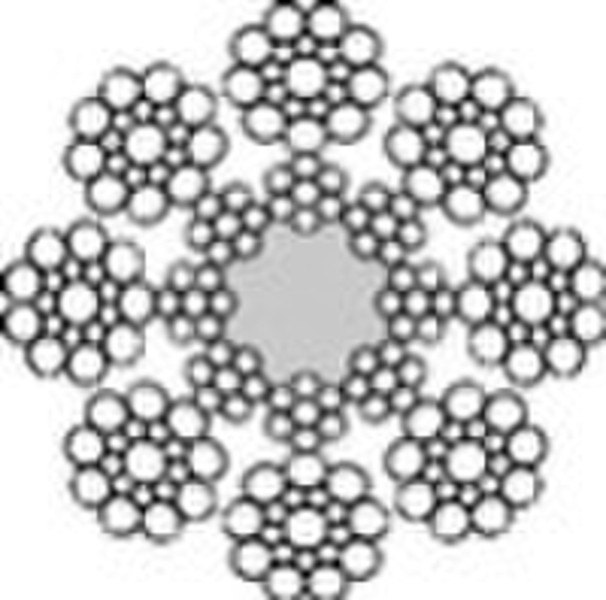

For many years our elevator ropeworks standard PAWO F3 has a proven history in many types of traction elevator applications.The outer strands are designed in Seale construction. The 9 thicker wires of the outer strand layer offer a higher wear resistance.The rope is primarily used where the service life is more defined by the attack of the drive sheave than by permanent bends. Thanks to the steel wire rope core a higher metallic cross section is achieved, in conjunction with excellent elongation properties. Deformations of the rope cross-section, e.g. in V-grooves are reduced to a large extent. The fiber content in the core of the steel wire rope works as a lubricant reservoir. Tensile Grade: 1570N/mm2, also available in other grades and standards, such as JIS, etc. Diameter: 6-20 mm Construction: 8*19 Seale with steel reinforced core, regular lay Nmber of load bearing wires: 152 low to mid rise medium number of bending cycles normal to high frequency wear-resistant low stretch extended service life

Условия поставки и упаковка

Packaging Detail: Wooden reel/plywood box wrapped with PP film, Seaworthy Delivery Detail: Within 30 days after payment

Порт: shanghai

Условия оплаты

Электронный перевод

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: