Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

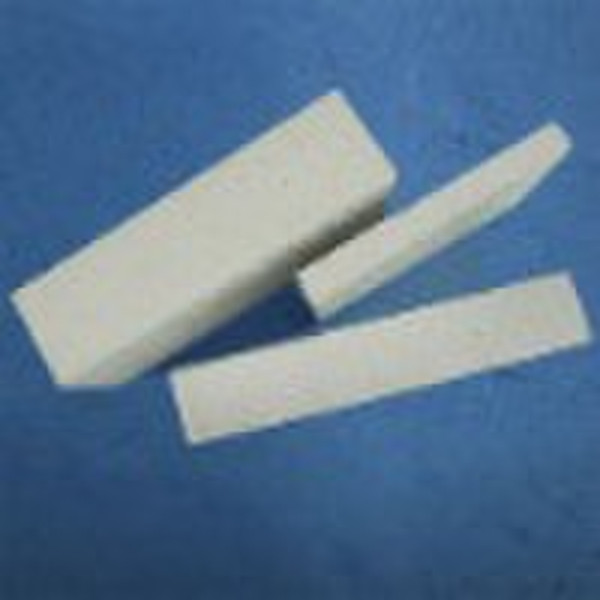

кислотостойкий кирпич

KinSu Liu

Контактное лицо

Основные данные

| Место происхождения | Jiangxi China (Mainland) |

|---|---|

| Тип | Керамические шарики |

Detailed Selling Lead Description Ceramic bricks and plate are widely used as liners in reaction furnaces, drying towers,baths, floors and channels where corrosion resistance is needed. Ceramic strip arch are used as support structures for bottom packing in dry absorption towers of concentrated sulphuric acid. The product has the advantages of better compatibility, lower cast, easier design and manufacture, shorter overhauling period and longer life time than cast iron ball arches. Their hole-opening rate is more than 60%. They have the properties of good anti-corrosion and acid-proof, good heat proof and stability, and uniform air distribution. Products in required sizes can be made according to the tower diameter. We offer construction direction for customers.Physical features of Acid-resistant Brick Specific gravity 2300-2400kg/m3 Water absorption <1% Bending strength <39.2Mpar Urgent cold and heat resistance 20-200oc Strength Mohs8-grade Chemical features of Acid-resistant Brick SiO2 Al2O3 K2O Na2O CaO MgO Fe2O3 Acid resistance 69.8 22.5 2.7 0.95 0.82 0.12 0.49 99.8 Specifications and Types Name Size Name Size Standard brick 230*113*65 Acid-resistant ceramic plate 180*110*15-30 Rectangle-brick 230*65*65 Acid-resistant ceramic plate 150*150*15-30 Horizontal wedge brick 230*113*55/65 Acid-resistant ceramic plate 150*70*15-30 Horizontal wedge brick 230*113*25*65 Acid-resistant ceramic plate 100*100*10 Vertical wedge brick 230*113*55/65 Acid-resistant ceramic plate 80*80*10 Vertical wedge brick 230*113*25*65 Acid-resistant ceramic plate 50*50*10

Условия поставки и упаковка

Packaging Detail: bags/cartons Delivery Detail: 30 days

Порт: shanghai/guangzhou/tianjin

Условия оплаты

Аккредитив

Электронный перевод

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: