Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

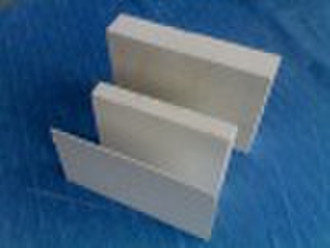

керамическая доска волокна теплоизоляции

Цзыбо, Китай

86-0533-7223858

MR XU

Контактное лицо

Основные данные

| Применение | Теплоизоляционные материалы |

|---|---|

| Толщина | 10-50mm |

| Ширина | 400 500 600 1000mm |

| Длина | 600 900 1000 1200mm |

| Химический состав | al2o3 |

| Рабочая температура | 1200℃ |

| Диаметр волокна | 2-3um |

| Теплопроводность | 0.085(400℃) |

| Место происхождения | Shandong China (Mainland) |

| Номер Модели | (High Aluminum) |

| Бренд | xiangmin |

| Класс | HA (Высокое содержание алюминия) |

Mechanism of ceramic fiber board (Ceramic Fiber Board)Product Description: Processed by vacuum molding process, the strength of these products is higher than fiber blanket and vacuum molding carpet, suitable for products with high strength requirements of high-temperature areas. Technical characteristics: Low thermal conductivity, lo w heat capacity; excellent thermal stability and thermal shock resistance; high compressive strength, long service life; non-brittle material, toughness, good; size precision flatness good; easy to cut to install, easy construction; excellent anti-erosion properties; continuous production, fiber distributed evenly, stable performance; excellent acoustic noise performance. Application: Petrochemical industry: high-temperature furnace lining hot face material; Kiln Construction: hot-face refractory (alternative fiber blanket), has been heavy refractory lining, expansion joints; light: industrial and domestic boiler combustion chamber liner; iron and steel industry: expansion joints, back lining insulation, thermal insulation films and molded insulation; non-ferrous metals industry: tundish and flow slot cover for pouring copper and copper alloys; Ceramic Industry: lightweight kiln car structure and furnace hot face lining body, the furnace and the temperature zones separated by a fire block material; the glass industry: molten pool is lined insulation, burner blocks.Operating temperature: depending on material conditions of use, the heat source type and atmosphere.Project Name Normal Standard Purity type Alumina-type Zr-Al-type Zirconium type Classification temperature () 1050 1260 1260 1400 1400 1400 Operating Temperature () ≤ 1000 1000 1100 1200 1300 1400 Bulk Density (kg/m3) 280 ± 15 280 ± 15 280 ± 15 280 ± 15 280 ± 15 280 ± 15 Permanent linear shrinkage (%)(Volume density 285kg/m3) 1000 × 24h ≤ -4 1000 × 24h ≤ -3 1100 × 24h ≤ -3 1200 × 24h ≤ -3 1300 × 24h ≤ -3 1400 × 24h ≤ -3 Thermal Conductivity (W / mk)(Volume density 285kg/m3) 0.085 (400 ) 0.132 (800 ) 0.180 (1000 ) Compressive Strength (MPa)(Thickness direction of compression 10%) 0.5 0.5 0.5 0.5 0.5 0.5 Chemical Composition (%) AL2O3 44 - 45 45 - 46 47 - 49 52 - 55 47 - 51 39 - 40 AL2O3 + SiO2 96 97 99 99 ---- ----- AL2O3 + SiO2 + ZrO2 ---- ----- ---- ---- 99 99 ZrO2 ---- ---- ---- ---- 8 - 9 15 - 17 Fe2O3 "1.2 "1.0 0.2 0.2 0.2 0.2 Na2O + K2O ≤ 0.5 ≤ 0.5 0.2 0.2 0.2 0.2 Product Code XMGX-115 XMGX-215 XMGX-315 XMGX-515 XMGX-615 XMGX-715 Product Specification (mm) 900 * 600 * 50; 600 * 400 * 25 (the other specifications according to user requirements production)

Условия поставки и упаковка

Packaging Detail: carton box Delivery Detail: within7-15days

Порт: qingdao

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: