Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

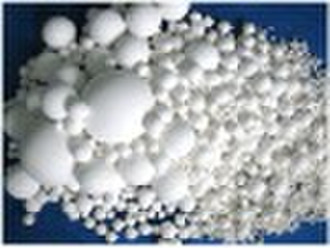

керамическая чистый бал алюминия

HICY ZENG

Контактное лицо

Основные данные

Ceramic Alumina Ballis broadly utilized as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas, for example, petroleum, chemical industry, chemical fertilizer, natural gas, and environmental protection etc. There are lots of merits for it, for instance, the stronger resistance to high temperature and high pressure, lower ratio of the moisture absorbing, more stable chemical properties, and so on. It is capable of enduring the corrosion of acid, alkali, and organic solvent. In addition, it can also bear the rapid transitions of temperature during the operation. In fact, its principal functions are to accelerate the distribution of gas or liquid, and support or protect the active catalyst, which especially has the relevantly lower mechanical strength. Chemical Compositions Chemical compositions ContentAl2O3 (Standard value +4) %Al2O3+SiO2 ≥92%Fe2O3 <1% Physical and chemical properties Main crystal phasesAl2O3 Property FeldstarFeldstar-mulliteMulliteMullite-corundumCorundum20-2525-4545-7070-90>90Bulk density, (g/cm3) 1.3-2.0Water sorption, (%) <3<1Acid resistance(%) >98Alkali resistance(%) >80>82>85>90>95Spalling resistance(°C) >250>300>500>700>800Refractoriness(°C) >1300>1400>1500>1600>1700Crushing strength, KN/particleØ6>0.40>0.45>0.6>0.7>0.8Ø8>0.7>0.8>0.9>1.0>1.2Ø10>0.9>1.0>1.2>1.5>1.8Ø13>1.2>1.3>1.6>1.8>2.0Ø16>1.5>1.6>1.8>2.3>2.6Ø20>1.8>2.0>2.3>2.8>3.20Ø25>2.5>2.8>3.2>3.6>4.0Ø30>2.8>3.0>3.5>4.0>4.5Ø38>4.0>4.5>5.0>5.5>6.0Ø50>6.0>6.2>10.0>10.5>11.0Ø60>8.0>8.5>11.0>12.0>14.0Ø75>13.0>11.0>12.0>14.0>15.0Note: It may only be provided as the reference for the bulk density, and it is not as the evidence of check. Notice to ordering goods: a) When ordering goods, customers should introduce the radical situations of the equipment, including the sizes of reactors, and the operational temperature etc. b) Customers should provide the specification, types, and the total content of Si, Al related to the required product. c) As the inert ceramic ball belongs to the natural tight stacking in the reactors, customers should consult with our technological staff to determine the amounts according to the practical loading volume, and remain 15-20% margins

Условия поставки и упаковка

Packaging Detail: woven bags+plastic film wrapped+palletized or steel drum or wooden box Delivery Detail: 20 days for 20' GP

Порт: Shanghai / Guangzhou

Условия оплаты

Аккредитив

Электронный перевод

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: