Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

брелок

Ada Hu

Контактное лицо

Основные данные

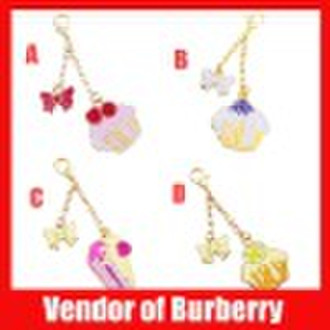

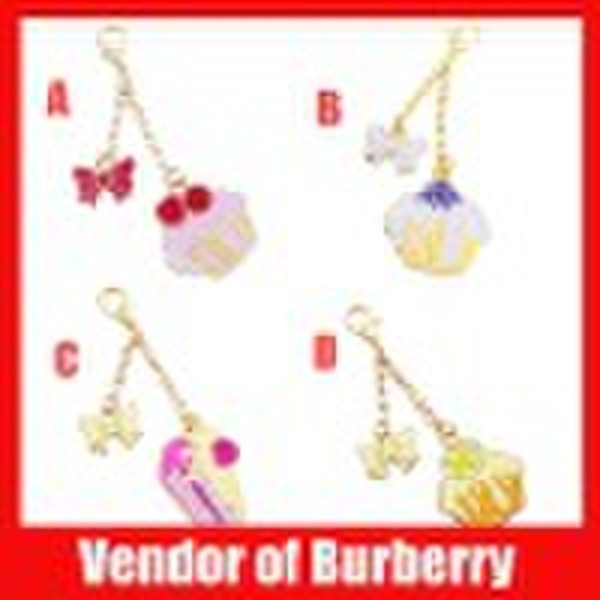

Technique Description: A set of Keychains Size:1.69" for Cake;1"×0.787" Thickness:0.0787" Material:Zinc alloy Weight:23G/PC Plating:Gold(They will not rust or tarnish as we add protection layer after plating.),Nickel or consult Accessory:Keychains Storage:keep in cool and dry place away from corrosive liquid. QC:Salt Fog Test/Acid Resistance/Alkali Resistance Test What we can do: Excellent quality,reasonable price,prompt delivery,satisfying service 1)Item Name:A set of keychains 2)Can be produced according to customer’s design,samples & requirement 3)Variouse designs and colors are available. 4)Good quality and competitive prices 5)OEM orders are welcome. 6)Prompt Delivery Packing: 1pc/1 box or bag.700pcs/carton,16.1/17.1KGS in export carton size in 34×24×20CM or according to customer designs. Production Process: Steel mold Injection Cutting Polishing Electro plating assembling with Inspecting Packing Introduction: Zinc alloy is the process by injection mold. The quality is harder so good polish can be handled to achieve better metallic surface finish. In the meantime, the cut-out part on the product can be quite tiny and reach better 3D effects in comparison with Stamping process. Antique plating is ideal plating process for zinc alloy. In-fill coloring is also available. Pantone color chart can be guided to match.

Условия поставки и упаковка

Packaging Detail: Polybag or consult Delivery Detail: 15 days or consult

Условия оплаты

Аккредитив

Электронный перевод

MoneyGram

Paypal

Вестерн Юнион

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: