Каталог

-

Каталог

- Автомобили и мотоциклы

- Безопасность и защита

- Бизнес

- Бытовая техника

- Бытовая электроника

- Детали машин и услуги по их изготовлению

- Дом и Сад

- Здоровье и медицина

- Игрушки и хобби

- Изделия из металла

- Измерительные и анализирующие приборы и инструменты

- Инструмент

- Красота и личная гигиена

- Мебель

- Мероприятия по охране окружающей среды

- Минералы и металлургия

- Модные аксессуары

- Обувь и аксессуары

- Одежда

- Освещение

- Подарки, сувениры

- Продовольственные товары и напитки

- Промышленное оборудование и техника

- Резина и пластмассы

- Сельское хозяйство

- Специальное оборудование

- Спорт, отдых и досуг

- Сток

- Строительство и недвижимость

- Текстиль и кожа

- Телекоммуникации

- Товары для офиса, учебы. Канцтовары

- Транспорт

- Упаковка и печать

- Химикаты

- Часы, Украшения, Очки

- Чемоданы, сумки

- Электронные компоненты, оборудование, принадлежности

- Электротехническое оборудование и принадлежности

- Энергия

Filters

Search

5,5 Штамповка машины

Далянь, Китай

86-411-86852615

Zhenhua Chong

Контактное лицо

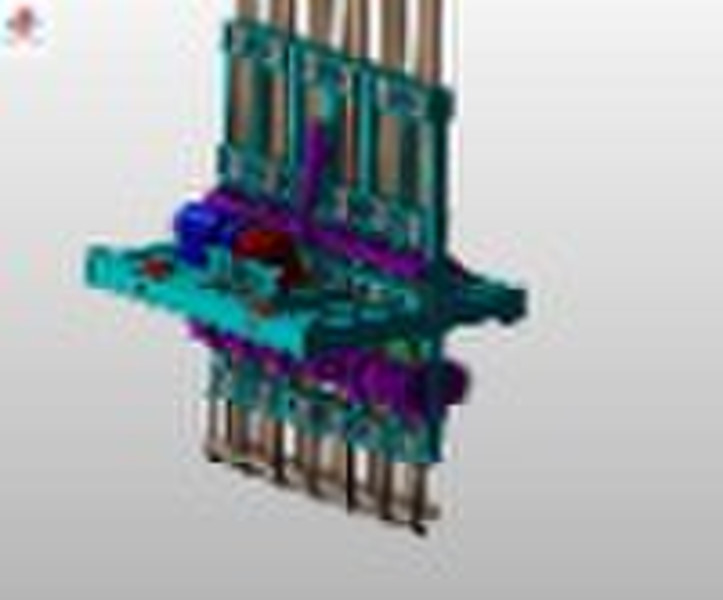

Основные данные

5.5m stamping machine is the product that was independently developed, designed and manufactured by DHI-DCW Group Co., Ltd. in 2006. It is a complete set of environmental-friendly coal side-charged stamping machine and DHI-DCW has its independent intellectual property. The 5.5m coke oven machinery is composed of coal charging car, coke pushing machine (or pushing machine with coal charging car), coke guide machine, stamping machine, electric locomotive, coke quenching car, flaming-type smoke guide car (U-shaped pipe smoke guide car )etc. 5-2 serial sequence technology is used for the stamping machine. The widths of carbonizer in matching with it are 500mm, 550mm etc. maximum coke output for single hole is 30.1t. The stamping machine has the advantages of environmental protection, high efficiency and high reliability. Technological Characters of Coal Charging Car for Stamping Machine One-spotting technology is used; VVVF speed control technology is used for the traveling device, which is operated smoothly without shock; VVVF speed control technology is also used for the coal charging drive, which is operated smoothly; the encapsulation technology is used for coal charging operation; the dust and fume are efficiently controlled when the coal is charged at machine side; and the scrapper blades are used for spillage coal reclaiming. Technological Characters of Coke Pushing Machine for Stamping Machine One-spotting technology is used; VVVF speed control technology is used for the traveling device, which is operated smoothly without shock; the eddy current speed control technology is used for coke pushing operation with mature technique and smooth operation; and the coke pushing machine ahs the functions of mechanized automatic opening, mechanized spillage coke collecting, mechanized oven door cleaning and reliable jamb cleaning. Technological Characters of Dust Removal Coke Guide Machine for Stamping Machine One spotting technology is used for the coke transfer car; VVVF speed control technology is used for the traveling device and the coke transfer car is operated smoothly without shock and has the functions of mechanized door opening, dust and fume collecting at the coke side in the round by means of dust collecting trunk or belt car, spillage coke collecting by means of dump bucket, mechanized oven door cleaning, reliable jamb cleaning and mechanized wharf cleaning. Technological Characters of Electric Locomotive for Stamping Machine One spotting technology is used for the electric locomotives, which are divided into two kinds, i.e. dry coke and wet coke electric locomotives; VVVF speed control technology is used for the traveling device, which is operated smoothly without shock and has the external hanging construction of driving unit. Technological Characters of Coke Quenching Car for Stamping Machine The pointing coke receiving and quenching technology is used; and the car is pneumatically opened. Technological Characters of U-shaped Pipe Smoke Guide Car The U-shaped pipe dust removal mode and one spotting technology are used. The U-shaped pipe smoke guide car has the advantages of dust removal, environmental protection and investment saving. VVVF speed control technology is used for the traveling device, which is operated smoothly without shock. The automatically mechanized lid lifting function is realized in the internal of U-shaped pipe with high sealing property. The functions of stand pipe cleaning and high- and low- pressure ammonia water operation are provided. Technological Characters of Stamping Machine The stamping machines are divided into two types, i.e. 21-hammer mobile stamping machine and 24-hammer stationary stamping machine. Adjustable single hammer can be realized by central moment of eccentric cam. The stamping machine has the functions of automatic detecting the stamping hammer, smooth operation and low noise.

Условия поставки и упаковка

Packaging Detail: seaworthy packing will comply with international standards, which is suitable for sea transportation and land transportation. Delivery Detail: 12 months exw after receiving the advance payment

Порт: Dalian

Условия оплаты

Аккредитив

Электронный перевод

-

Способы оплаты

Для оплаты товаров и услуг на нашем портале, Вы всегда получаете счет, в котором Вам необходимо самостоятельно указать свои данные.

Мы принимаем к оплате: