Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

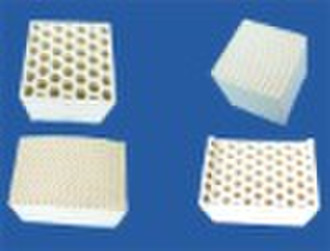

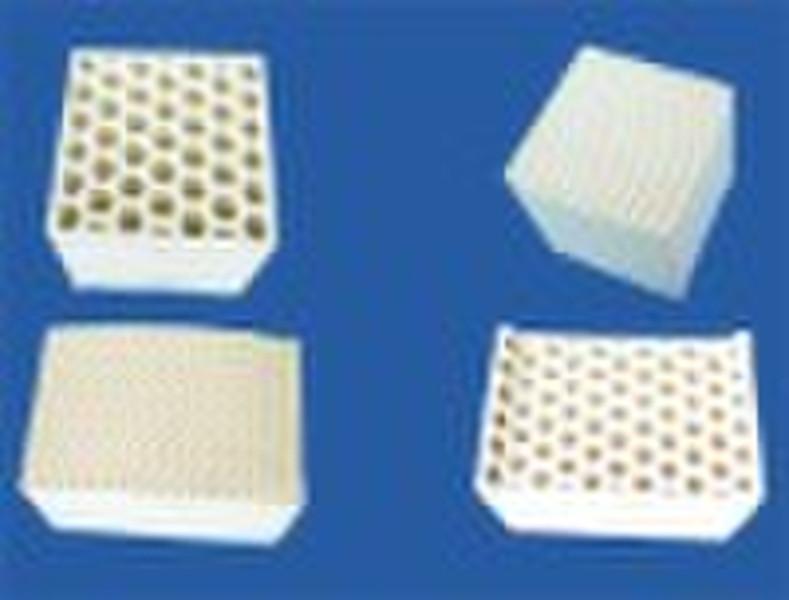

Honeycomb ceramics,Honeycomb refractory ceramics

original price: 0,40 USD

Yixing, China

Production capacity:

10000 Piece / Day

michael yin

Contact person

Basic Information

| Place of Origin | Jiangsu China (Mainland) |

|---|---|

| Type | Ceramic Plates |

| Application | Refractory |

| Material | Alumina Ceramic |

Honeycombceramics Honeycombceramicregeneratorisaregenerativehigh-temperaturecombustiontechnology(HTACtechnology)thekeyandcorecomponents.Regenerativehightemperaturecombustiontechnology(HTACtechnology)isanewconceptofcombustiontechnology,whichthefluegaswasteheatrecoveryandefficientcombustionandreduceNOxemissionsfromorganicallyintegratetechnologiestoachieveenergyefficiencyandlimitthelimittoreduceNOxemissionsfromvolumeofadualpurpose.HoneycombceramicregeneratorhasbeenwidelyusedinmetallurgicalmachineryindustryavarietyofPusher-typefurnace,reheatingfurnace,heattreatmentfurnace,forgingfurnace,meltingfurnace,ladle/tundishtoasters,soakingfurnace,radianttubeburners,hood-typefurnace,blastfurnacehotblaststove;buildingmaterialsindustry,avarietyofceramickilns,allkindsofglassfurnace;petrochemicalindustry,avarietyoftube-typefurnace,crackingfurnaceandotherindustrialfurnaces. Specifications Specifications 1 2 3 4 5 6 L×W×H/mm 150×150×300 150×150×300 150×150×300 100×100×100 150×100×100 100×100×40 Holes 25×25 40×40 50×50 31(28) 36×24 48 Holegridwidth/mm 4.9 3.0 2.26 2.65(3.0) 3.1 1.57 Thickness/mm 1.0 0.7 0.7/0.55 0.55(0.55) 1.0 0.5 Surface/m2/m3 540 825 1005 1065(990) 760 1510 OpenRatio/% 67 65 57/64 67(91) 55 57 Physicalproperties Performance AluminumPorcelain Mullite DenseCordierite cordieritePorous Stoneware Corundum Mullite-cordierite Density >2.7 >2.9 >2.4 >1.9 >2.3 >3.2 >2.9 thermalexpansivity/20~1000C/106·C-4 5~7 5.5~6.5 2.5~3.5 1.25~2.5 5~7 6~7 <5 Heatcapacity/20~1000C/J/Kgk 1100~1300 1100~1300 800~1200 750~900 800~900 1300~1400 1100~1300 Heatshock/k min200 min230 min250 min360 min150 min260 min300 maximumoperationtemperature/k 1400 1600 1300 1300 1150 1750 1550 Chemicalproperties Performance AluminumPorcelain Mullite DenseCordierite Porouscordierite Stoneware Corundum Mullite-cordierite SiO2 40~45 25~30 45~52 46~52 68~75 8~11 28~36 AL2O3 48~55 66~72 32~36 32~37 20~26 85~92 55~65 MgO - - 5~8 12~16 0.15~0.25 1.8~2.5 2.5~3.2 Fe2O3 <1.0 <1.0 <1.0 <1.0 <1.2 <0.5 <0.8 Na2O+K2O+CaO 4.0~5.5 <1.0 <1.0 <1.0 2.5~4.0 0.5~1.2 <1.0 TiO2+BaO - - <0.5 <1.0 <0.5 - -

Delivery terms and packaging

Packaging Detail: 50pcs/bag Delivery Detail: 15days after receive your deposit

Port: shanghai

Payment term

Letter of credit

Telegraphic transfer

MoneyGram

Western Union

-

Payment Methods

We accept: